You’ll improve manufacturing performance by studying real cases that define problems, test countermeasures, and show measurable results, then applying proven tools like value stream mapping, standard work, and PDCA to remove waste and cut lead time. You’ll align projects with OKRs and governance to sustain gains, while big data, SPC, and real-time dashboards expose bottlenecks and energy drains. With this structure, you can scale wins across plants and avoid common pitfalls, but the sequence matters next.

Key Takeaways

- Use structured case studies to define problems, detail solutions, and quantify impact with cost, efficiency, and energy metrics for repeatable improvement.

- Lean and value stream mapping expose bottlenecks; e.g., ACS cut costs 65%, doubled throughput, and slashed scrap from 24% to 1.8%.

- Target quick sustainability wins: lighting upgrades, air leak fixes, and ventilation tuning deliver six-figure savings and sustained energy reductions.

- Unify real-time ERP, sales, and IoT data to predict failures, stabilize supply, and close visibility gaps across order-to-delivery.

- Standardize work, track daily KPIs, and run PDCA; rebalance cells and attack downtime to compress lead time without new capital.

Understanding Manufacturing Case Studies

Why do manufacturing case studies matter? They give you a structured, evidence-based view of how a specific problem was defined, solved, and measured, so you can adapt proven methods with less guesswork. You should profile the customer to set context, outline the challenge with clear constraints, describe the solution with implementation details, and present quantifiable results that prove impact.

Prioritize metrics like cost savings, efficiency gains, and energy reductions, since numbers validate claims and enable comparisons across projects. For example, you might track annual savings near $1.19 million or electricity reductions of 233,555 kWh per year to show operational improvement and sustainability benefits. By showing how targeted interventions drive outcomes, these studies become practical guides for repeatable performance improvement. In addition, aligning case study methods with organizational alignment principles—such as clear strategy, roles, and communication—helps ensure solutions scale effectively and sustain performance gains.

Top Manufacturing Case Studies

How do the best manufacturing case studies translate methods into measurable gains you can replicate? Start by applying lean tools and value stream mapping to expose bottlenecks and waste, as Advanced Composite Structures did, cutting costs 65%, doubling throughput from 20 to 45 units per shift, and dropping scrap from 24% to 1.8%.

Use targeted diagnostics to capture quick wins, like Besam North America’s energy survey that identified lighting upgrades and air leak fixes, saving 233,555 kWh and $25,776 annually.

Targeted diagnostics deliver quick wins: energy survey found lighting and air leaks, saving 233,555 kWh and $25,776 annually

Redesign flow to remove delays and excess motion, following Canyon Creek’s approach that delivered about $1.19 million in annual savings.

Deploy Lean Six Sigma to lift capacity over 50% without new capital, or stabilize scheduling and downtime to turn losses into profit and revenue growth.

To sustain these gains, embed continuous communication and feedback loops using OKRs to align teams on measurable objectives and regularly review progress against key results.

Sustainable Manufacturing Practices

Building on the gains shown in top manufacturing case studies, you can embed sustainability into daily operations by targeting energy, materials, and process waste with the same rigor you apply to throughput and quality. Start with an energy walkdown, then act on no‑regret items: upgrade lighting, seal air leaks, and tune ventilation, as Besam did, capturing 233,555 kWh and $25,776 annually. Expand into material stewardship by tightening inventories, as Custom Print did by optimizing color mixing and ventilation, slashing chemicals 70% and electricity by $2,000 per month. Institutionalize recycling and closed‑loop reuse, following Guardian Automotives’ cullet and fiberglass program that saved $360,000. Sustain results through lean routines—value stream mapping, standard work, and daily Gemba checks—so energy and emissions shrink with waste. Embed regular reviews and governance rhythms to connect sustainability projects to aligned OKRs and maintain execution momentum across teams.

1) Bright, efficient LEDs replacing aging fixtures.

2) Tight door seals stopping invisible drafts.

3) Reused materials flowing back into production.

4) A clean value stream map guiding daily decisions.

Leveraging Big Data in Manufacturing

You can treat big data as a practical toolkit for sharper decisions across your plant, turning raw signals from orders, machines, and logistics into actions that forecast demand, stabilize supply, and lift yield. Start by unifying real-time data from sales, ERP, and shop-floor sensors so you can see demand shifts early, align materials, and avoid costly changeovers. Use proven cases as guides: Alcar Ruote uses Oracle Fusion Cloud to surface live demand and IoT streams to predict failures, while Construction Specialties traces orders from marketing to delivery, closing visibility gaps. Apply simulation like Tata Steel to test crane and ladle layouts before changing equipment. Establish benchmarks, track defects, waste, and cycle times, then iterate, because measurement-driven adjustments compound performance gains. Complement big data with SQCDP Boards that visualize Safety, Quality, Cost, Delivery, and People metrics in real time to turn insights into daily, team-driven actions.

Proven Techniques to Improve Manufacturing Efficiency

Data only pays off when it shapes everyday routines on the floor, so turn insights into proven techniques that compress lead time, raise throughput, and cut waste without new capital. Start by tightening flow and eliminating non-value-added time, since lean projects have delivered dramatic results, like Advanced Composite Structures cutting costs 65%, lifting output from 20 to 45 units per shift, and slashing scrap from 24% to 1.8%. Standardize work, track KPIs daily, and run PDCA to expose defects faster and lock in gains. Strengthen daily execution by ensuring organizational alignment, since aligned companies grow revenue faster and achieve higher profitability through clearer objectives and cross-functional collaboration.

Turn shop-floor data into daily habits that tighten flow, boost throughput, and crush waste without new capital.

- Map value streams, remove bottlenecks, and rebalance cells to cut travel and queues.

- Schedule by constraint, monitor intra-day, and attack downtime to boost capacity >50%.

- Reduce scrap with root-cause analysis, poka-yoke, and material controls.

- Audit energy, trim idle loads, and capture five-figure utility savings.

Frequently Asked Questions

How Do We Build a Cross-Functional Performance Improvement Team From Scratch?

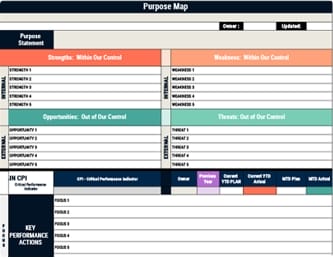

Start by defining the mission, scope, and success metrics, then secure an executive sponsor. Identify core functions—operations, quality, engineering, supply chain, finance, HR, and IT—and select one accountable representative from each. Draft clear roles, decision rights, and meeting cadence, and train the team on problem-solving, data literacy, and change management. Establish a project intake process, a common KPI dashboard, and a communication plan, then pilot quick wins to build credibility and momentum.

What KPIS Should Be on a Daily Tiered-Standup Dashboard?

Start with throughput, first-pass yield, scrap rate, on-time completion, and schedule adherence, then add downtime by cause, changeover time, and WIP levels, because these reveal flow and quality in real time like a lighthouse blazing brighter than the sun. Track safety incidents and near-misses daily, and include customer OTIF. Show staffing versus plan, critical shortages, and maintenance compliance. Use trend arrows and targets, escalate red items with owners and deadlines, and review countermeasures.

How Do We Calculate ROI for Frontline Worker Training Programs?

You calculate ROI by quantifying training benefits, subtracting costs, then dividing by costs. First, baseline key metrics, then measure post-training deltas: reduced defects, downtime, scrap, rework, injuries, and faster changeovers or cycle times. Convert gains to dollars using labor, throughput, and margin data. Include avoided overtime, lower turnover, and reduced hiring time if attributable. Total training costs include design, delivery, wages during training, travel, materials, and software. ROI = (Benefits − Costs) ÷ Costs.

Which Change-Management Tactics Sustain Improvements After Pilot Success?

Steady standards, structured systems. You sustain pilot gains by defining owners for each metric, embedding controls in standard work, and coaching supervisors to audit routines weekly. You align incentives to the metrics, publish visible scoreboards, and run daily huddles to review exceptions and trigger countermeasures. You document changes in simple SOPs, train with refreshers, and certify skills. You use change champions, reinforce behaviors with checklists, and schedule monthly retros to refine.

How Do We Align Incentives to Reduce Scrap Without Hurting Throughput?

Tie pay and recognition to both first-pass yield and on-time output, so you don’t reward speed that creates scrap.

Set team-level targets with weighted metrics—e.g., 50% quality, 50% throughput—and use control limits to avoid gaming.

Pay small, frequent bonuses for sustained improvements, not single spikes.

Align engineering and maintenance KPIs to defect prevention, provide real-time defect dashboards, run layered audits, and escalate chronic scrap to structured problem-solving with clear ownership and deadlines.

Conclusion

You’ll treat case studies like inconvenient mirrors, then actually use them, because facts beat folklore. Map value streams, standardize work, and run PDCA cycles, and you won’t need a crystal ball—just dashboards and OKRs that expose bottlenecks in real time. You’ll cut lead time, lift throughput, and trim energy costs, while governance stops pet projects from wandering. So, measure, learn, and iterate, since continuous improvement isn’t a slogan; it’s your repeatable method for predictable, sustainable performance gains.