When symptoms scream but causes whisper, you need Root Cause Analysis to separate noise from signal and stop repeat problems. You’ll define the issue precisely, gather cross-functional evidence, and use tools like 5 Whys, Ishikawa, Pareto charts, FMEA, and Fault Tree Analysis to trace failure pathways, prioritize contributors, and validate hypotheses. Then you’ll tie corrective and preventive actions to measurable outcomes and governance, ensuring fixes stick—if you choose the right method for your situation.

Key Takeaways

- Root Cause Analysis traces problems from symptoms to underlying causes to prevent recurrence and improve business performance.

- Core tools include 5 Whys, Ishikawa fishbone, Pareto charts, FMEA, and Fault Tree Analysis for structured investigations.

- Apply a step-by-step process: define the event, form a cross-functional team, cluster ideas, probe causes, and validate with data.

- Prioritize actions using Pareto and FMEA RPN scores, then implement CAPA with measurable metrics and weekly reviews.

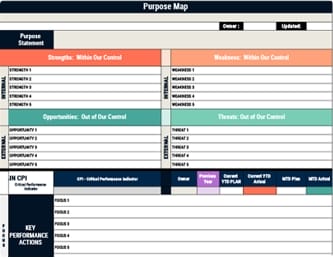

- Use dashboards and visual management to track fixes, ensure governance alignment, and sustain continuous improvement across functions.

What Is Root Cause Analysis and Why It Matters

Root cause analysis (RCA) is a structured way to trace a problem past its visible symptoms to the underlying factors that created it, so you can implement fixes that prevent it from happening again rather than repeatedly treating surface issues. You investigate how and why a failure occurred, then use that understanding to change processes or systems so recurrence drops. You’ll draw on systematic techniques like 5 Whys, Ishikawa diagrams, Pareto charts, FMEA, and fault tree analysis, selecting tools that fit the problem’s complexity and your time constraints. You ground conclusions in evidence, validate data, and document findings so corrective actions are credible and testable. You focus on learning and improvement rather than blame, ensuring decisions reflect facts, not assumptions. Incorporating RCA into broader organizational alignment practices ensures findings translate into strategic objectives, cross-functional collaboration, and continuous improvement.

Core Principles and Benefits of RCA

Why do effective teams invest time in core principles before choosing tools for root cause analysis? Because principles anchor your approach, ensuring you chase causes, not symptoms, and set up corrective actions that prevent recurrence. You start by asking how and why the failure happened, then gather concrete evidence that confirms or disproves your hypotheses, acknowledging that multiple root causes may interact. Aligned teams leverage shared values and clear communication to enhance engagement and ensure corrective actions connect to strategic objectives. You’ll apply disciplined data collection, systematic questioning, and clear documentation, which create traceability and accountability across decisions. With that foundation, you select tools that match the problem’s complexity, from a quick 5 Whys to structured methods like FMEA or FTA, rather than forcing a one-size-fits-all technique. The payoff is stronger problem solving, fewer repeat issues, deeper process understanding, and more effective CAPA outcomes in quality-focused environments.

How to Run an Effective RCA Step by Step

How do you turn a vague problem into a disciplined investigation that leads to lasting fixes? Start by defining the event precisely, including when, where, scope, and impact, then assemble a cross-functional team so you capture diverse perspectives. Facilitate brainstorming with an Affinity Diagram to group ideas logically and expose patterns you might miss in linear lists.

Use 5 Whys to move from symptoms to causes, documenting evidence at each step so you don’t guess or jump to conclusions. Validate suspected causes with data, using Pareto analysis to find the vital few and scatter plots to reveal relationships. Prioritize corrective actions with FMEA or risk-based scoring, setting measurable success criteria. Implement fixes as CAPA actions, then monitor outcomes and maintain living documents for sustained prevention. To sustain improvements, align RCA outputs with governance rhythms and performance dashboards so progress is tracked, ownership is clear, and plans adapt as conditions change.

Ishikawa Fishbone Diagram

Clarity takes shape in the Ishikawa fishbone diagram, a structured map that places your defined problem at the “head” and organizes potential causes along major “bones” such as People, Process, Machine, Materials, and Environment. You use it early in root cause analysis to cast a wide net, brainstorm systematically, and separate symptoms from underlying issues. Invite cross‑functional voices, then drill down by repeatedly asking why and how under each category until you find specific, actionable causes that suggest corrective actions. To enhance decision speed, apply the 1-3-10 second rule so teams can quickly see status, pinpoint issues, and know required actions as they analyze the diagram. 1. Picture the “head” naming the problem, with angled spines labeled People, Process, Machine, Materials, and Environment.

Use a fishbone diagram to systematically unveil root causes and drive targeted corrective actions.

2. Imagine sticky notes clustering on each spine, grouping related causes and sub‑causes.

3. See arrows cascading deeper as each “why” exposes hidden drivers.

4. Envision prioritized cause chains guiding practical fixes.

Pareto Chart

Curiously effective in narrowing your focus, a Pareto chart ranks categories of defects or causes from highest to lowest impact, then overlays a cumulative percentage line to show where the bulk of the problem resides. You use it to apply the 80/20 principle, quickly revealing the few categories that generate most of the trouble, so you can direct attention where it matters.

Build it by collecting data for a defined period or dataset, tallying frequency or impact by category, sorting the bars from highest to lowest, and plotting the cumulative percent to mark when you’ve captured the majority of impact. Interpret the breakpoint where the curve flattens, prioritize those leading bars, and allocate resources accordingly, because this pre-analysis narrows later investigation to high-yield issues. To turn insights into action, pair your Pareto with clearly defined Key Performance Actions that target the top categories, ensuring daily behaviors close the gaps revealed by the chart.

5 Whys Technique

After the Pareto chart points to the few categories causing most of the trouble, you need a way to unpack one category’s underlying mechanics, and the 5 Whys technique gives you that disciplined path. You repeatedly ask “why” to move from symptom to cause, usually five times, though fewer or more may be needed, and you ground each answer in observed data, not opinion. A facilitator keeps the team focused, links each why to the previous answer, and halts when you reach a process or system failure you can act on. Pair it with a Fishbone Diagram to structure causes, then confirm the final why predicts measurable improvement.

Use 5 Whys after your Pareto: link data-backed causes, stop at actionable system failure, verify measurable improvement.

1) A visible symptom on a dashboard.

2) A process step where it emerges.

3) A control that failed.

4) A corrective action with metrics.

To strengthen execution discipline, integrate 5 Whys findings into Visual Management Boards so teams can track KPIs, share outcomes, and drive timely adjustments.

FMEA, PROACT, Affinity Diagrams, and FTA

Why use multiple tools to move from potential failure to concrete prevention? Start with FMEA to proactively list where things can break, then score each failure mode for Severity, Occurrence, and Detection to compute an RPN, which lets you prioritize corrective actions. As S, O, or D rise, you assign more urgent mitigation and verification, ensuring resources align with actual risk. Use PROACT to structure your investigation, preserving evidence, staging the right experts, mapping logic trees to test causes, and tracking results so your RCA delivers measurable ROI. When qualitative inputs feel messy, apply Affinity Diagrams to cluster observations into themes that reveal likely root causes. For safety-critical risks, build a Fault Tree Analysis, decomposing the top event with Boolean logic for exhaustive prevention planning. Integrate these RCA tools into your documented Business Operating System to align roles, processes, and continuous improvement cycles across the organization.

Real-World Examples and Implementation Tips

Although tools can feel abstract until you see them in action, real-world RCA succeeds when you blend simple methods with disciplined follow-through: start a production defect investigation by mapping a Fishbone diagram across People, Process, Machines, Materials, and Environment, then facilitate a quick 5 Whys on the most suspicious branches to convert symptoms into testable causes, capture data as you go, and validate findings with small experiments. Next, use Pareto analysis to rank causes by impact so you focus resources on the few drivers that create most defects, then convert priorities into corrective and preventive actions with owners, due dates, and metrics. In manufacturing, apply FMEA to score risks, and in safety-critical work, use Fault Tree Analysis to ensure exhaustive prevention. To drive action and clarity, integrate RCA outputs into visual management boards with color-coded indicators and real-time updates so teams can spot issues quickly and sustain improvements.

1) Sketch the line, annotate failure points, photograph evidence.

2) Build a Pareto chart, circle the vital few bars.

3) Run an FMEA table, highlight top RPNs.

4) Link CAPA tasks to metrics, review weekly.

Frequently Asked Questions

How Do We Sustain RCA Outcomes Over Months Without Losing Momentum?

Sustain outcomes by translating fixes into standard work, clear owners, and measurable KPIs, then review progress in monthly cadence meetings. Tie metrics to dashboards, escalate misses with predefined triggers, and adjust countermeasures using PDCA. Keep training brief and recurring, rotate audits to prevent complacency, and document lessons in a shared repository. Align incentives and recognition with adherence and results, and ensure leadership models the behaviors, removes blockers, and communicates priorities consistently.

What Software Tools Best Support Collaborative, Cross-Site RCA Sessions?

You’ll get strong cross-site RCA support from Miro or Mural for shared fishbones and timelines, Microsoft Teams with Whiteboard and Forms for structured capture, and Lucidchart for real-time diagramming that locks versions. You should add Confluence or Notion for decision logs, Jira or Azure DevOps for action tracking, and Zoom with breakout rooms for subgroup analysis. Configure templates, permissions, and timestamps, automate minutes, and integrate tools to keep artifacts consistent, searchable, and auditable.

How Should Remote or Hybrid Teams Document and Share RCA Artifacts?

Document RCA artifacts in a centralized, versioned workspace, and use templates for problem statements, timelines, causal diagrams, and action logs. Capture decisions in meeting notes, link evidence, and tag owners, dates, and statuses. Store visuals and data in linked folders, enforce naming conventions, and apply permissions for sensitive items. Share via a living summary page, automate notifications for updates, and schedule periodic reviews to validate effectiveness and retire or revise actions.

How Can RCA Integrate With Agile Sprints and Devops Pipelines?

Of course, because you love fixing the same bug twice, you’ll embed RCA into sprints and pipelines. Add lightweight 5-Whys to sprint retros, track actions as backlog items, and set SLAs for corrective tasks. In DevOps, trigger blameless postmortems on incidents, automate evidence capture from logs and CI/CD, and gate releases on verified fixes. Use templates, tag work with components, and review systemic patterns each PI to prevent recurrence.

What Training Cadence Builds Organization-Wide RCA Capability Effectively?

Adopt a layered cadence: start with a 2–3 hour kickoff for all teams, then run weekly 60-minute practice labs for a month, followed by biweekly case reviews for two months, and shift to monthly communities of practice.

You supplement this with quarterly advanced workshops, manager coaching every six weeks, and just-in-time microlearning tied to incidents. You measure adoption through RCA quality checks, cycle-time impact, recurrence rates, and cross-team participation.

Conclusion

You now know why RCA matters, how to run it, and which tools to use, yet the real test starts when your next incident hits. You’ll define the event, map causes with a fishbone, ask 5 Whys, validate with Pareto, then prioritize risks via FMEA, all while aligning CAPA to metrics and governance. Start small, document rigorously, and close feedback loops, because when the next pattern emerges, you’ll be ready to trace it to the source—and act.