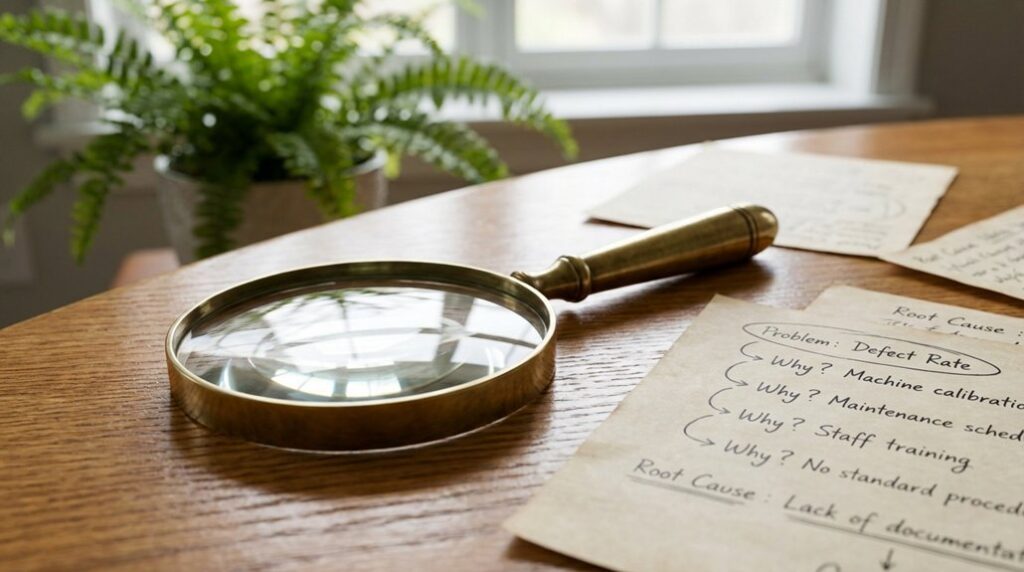

Picture laying out a trail of breadcrumbs from a problem to its cause, each step tested by asking “Why?” until you reach something you can change. You’ll define a precise problem, gather cross‑functional voices, and document each answer with evidence, not guesses, so corrective actions are clear, owned, and timed. With simple tools like a fishbone diagram and PDCA, you’ll avoid blame, expose system gaps, and set up sustained improvement—if you structure the session right.

Key Takeaways

- Frame a clear, data-informed problem statement and assemble a cross-functional team with a neutral facilitator.

- Ask “Why?” at least five times, attaching evidence and noting assumptions at each step.

- Stop when you reach a controllable root cause or learning plateaus; avoid blame, focus on process.

- Document the Why chain on a shared board, assign corrective actions with owners, dates, and follow-up checks.

- Integrate with fishbone, A3, PDCA, and link outcomes to OKRs/KPIs for sustained continuous improvement.

What Is the 5 Whys Method and Why It Matters

Why does a simple question like “Why?” solve complex problems so effectively? The 5 Whys method gives you a disciplined way to move past symptoms and uncover the root cause, so you don’t waste effort on surface fixes. Originating with Taiichi Ohno in the Toyota Production System, it asks you to pose “Why?” repeatedly—often five times—until you reach a cause you can act on, though you can stop earlier if the root is clear.

You focus on facts, not blame, and include cross-functional voices to expose human, procedural, or systemic drivers. You then identify corrective actions aligned to the true cause. While quick and accessible, you often strengthen it by pairing with tools like fishbone diagrams, A3 thinking, or FMEA to validate logic and ensure robust solutions. When using 5 Whys, tie findings to aligned OKRs to connect root causes with execution and ensure accountability in strategy deployment.

Step-by-Step Guide to Running a 5 Whys Session

How do you run a 5 Whys session so it’s structured, efficient, and evidence-based from the start? Begin by assembling a cross-functional team that includes process owners, people directly involved in the work, a designated facilitator, and key stakeholders, since diverse perspectives reduce blind spots. Frame a clear, focused problem statement, then bring relevant data—logs, timestamps, defect counts, and customer reports—so you’re not guessing.

Ask “Why?” at least five times, probing deeper each round, and stop when you reach a controllable root cause or when learning plateaus. Document each Why chain on a shared board, attach the supporting evidence, and note assumptions. Assign owners to draft corrective actions that address causes, not symptoms, define due dates, and plan follow-up checks to confirm the issue doesn’t recur. Incorporate a quick visual check using the 1-3-10 rule to ensure the problem, root cause, and next actions are immediately clear to the team.

Templates, Tools, and Documentation for Consistent Results

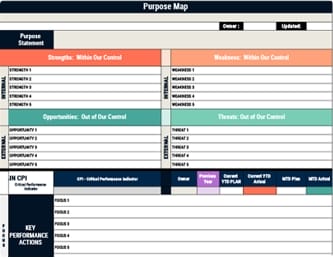

A structured set of templates and tools turns 5 Whys from an ad‑hoc conversation into a repeatable, auditable practice, giving you a clear record of what was asked, what was learned, and what’ll be done. Use a standard template that prompts you to define the problem statement, list each Why with its answer, identify the root cause, and specify corrective actions, owners, and due dates, so nothing critical is missed. Capture the Why chain on a visual board, whether a whiteboard or digital canvas, to make reasoning visible and enable transparent collaboration. Save documentation in a versioned format, such as a PDF snapshot per revision, to preserve history. Link your template to fishbone, A3, or PDCA artifacts, and track follow‑up actions until completion. To ensure action translates into results, connect each 5 Whys outcome to your CPI→KPI→KPA execution loop so root causes inform critical outcomes, the right performance indicators, and the daily behaviors that drive improvement.

People, Roles, and Best Practices for Effective Analysis

Sometimes the difference between a superficial 5 Whys session and a rigorous root-cause analysis comes down to who’s in the room and how they work together, so assemble a balanced team and set clear roles from the start. Include the process owner, people who do the work, a neutral facilitator to guide the flow, and stakeholders who can approve changes. Set expectations: seek facts, visualize the process, and keep discussion blameless to surface hard truths. Use complementary tools to deepen insight and reduce bias. To reinforce outcomes and sustain improvements, align the analysis with strategic alignment and keep continuous communication and feedback loops in place.

- Involve cross-functional voices to spot process gaps, not just technical glitches.

- Use fishbone diagrams, A3 thinking, FMEA, and PDCA to structure logic and verify risks.

- Capture decisions in digital whiteboards or Lean software to track actions and accountability.

Real-World Examples, Limitations, and When to Use Other Methods

Ever notice that real 5 Whys results point to process flaws more than broken tech, revealing issues like unclear work instructions, handoff gaps, or staffing shortfalls rather than a faulty machine? You’ll often find that “forgot” or “no time” hides deeper causes like missing standard work, poor training, or overloaded schedules, so push past symptoms to policy and workflow fixes. Acknowledge limitations: different facilitators can reach different answers, and one why-chain may miss parallel causes. Use cross-functional teams, data, and time-stamped evidence, and split multiple problems into separate lanes to keep causes distinct. For complex, interdependent issues, pair 5 Whys with fishbone diagrams to map categories, FMEA to prioritize failure risks, and PDCA to test and refine countermeasures, ensuring durable improvements. Strengthen outcomes by checking that countermeasures align with shared values and strategic objectives, improving engagement and execution across teams.

Frequently Asked Questions

How Do We Measure ROI From 5 Whys-Driven Improvements?

You measure ROI by comparing the financial gains from reduced defects, delays, or rework against the total cost of implementing 5 Whys-driven fixes. First, baseline key metrics like cycle time, scrap rate, incident count, and warranty spend. Next, track post-improvement deltas, monetize savings, and include revenue lifts from higher throughput. Sum implementation costs—labor hours, training, tooling, and downtime. Finally, calculate ROI = (Net Benefits ÷ Total Costs) × 100%, and validate with trend analysis.

What Data Privacy Concerns Arise During Root Cause Investigations?

Like Odysseus navigating sirens, you face privacy risks: you might collect excessive personal data, expose sensitive identifiers, or mix datasets that enable re-identification. You risk insecure storage, weak access controls, and shadow copies in notes or screenshots. You could breach consent, retention limits, or cross-border transfer rules. Mitigate by applying data minimization, role-based access, pseudonymization, encryption, audit trails, documented consent, defined retention, DPIAs, and vendor due diligence, then train investigators accordingly.

How Can AI Tools Augment—Not Replace—Human 5 Whys Facilitation?

You can use AI to prepare clean data, surface patterns, and draft initial “why” chains, while you retain judgment, context, and facilitation. Let AI cluster incidents, highlight anomalies, and suggest hypotheses, then you validate evidence, refine questions, and manage group dynamics. Configure prompts to avoid leading conclusions, and use AI to map cause-effect links, track assumptions, and generate testable experiments, while you set boundaries, ensure accountability, and decide when the analysis is sufficient.

How Should Remote or Hybrid Teams Run Asynchronous 5 Whys Effectively?

Start with a shared “evidence locker,” like a pit crew’s tool cart, containing the incident summary, logs, and screenshots. You then define the problem statement, timebox each “why” to 24–48 hours, and assign a rotating owner to synthesize threads. Use a structured template, threaded comments, and emoji voting to converge. Capture assumptions, request counterexamples, and tag data sources. Conclude with a verified root cause, specific actions, owners, deadlines, and a brief playback recording.

What Cultural Indicators Show 5 Whys Maturity Across an Organization?

You see 5 Whys maturity when leaders ask “what” and “how” instead of “who,” teams share blameless postmortems, and corrective actions target systems, not individuals. You document chains of causes, track leading metrics, and revisit fixes to validate learning. You standardize facilitation, train broadly, and make analyses searchable. You escalate cross-team causes, allocate time for root-cause work, and reward problem-finders, while audits confirm consistent depth, data use, and sustained outcomes.

Conclusion

You’re ready to run 5 Whys with purpose: define a crisp problem, gather a cross‑functional team, and peel back causes like layers of an onion until you reach a controllable root. Document each Why with evidence, map actions to owners and dates, and track results with PDCA to lock in gains. Use templates and fishbones for consistency, switch methods when data or complexity demands it, and keep iterating so continuous improvement becomes your steady, reliable engine.