You’ll treat operational excellence as a disciplined way to align daily work with strategy, cut waste, reduce defects, and adapt quickly so customers get consistent value. It blends Lean, Six Sigma, and Agile, backed by leadership commitment, data-driven decisions, and empowered teams that fix problems at the source. You focus on measurable outcomes, standard work, and continuous improvement cycles that build reliability and speed. Next, you’ll see how to structure this into a repeatable system.

Key Takeaways

- Operational excellence is a management philosophy focused on continuous improvement, aligning daily operations with strategy to maximize customer value and efficiency.

- It leverages Lean to eliminate waste, Six Sigma’s DMAIC to reduce defects, and Kaizen to drive ongoing process optimization.

- Core principles include customer-centricity, data-driven decisions, standardization, visual controls, and empowered problem-solving at the front line.

- A practical framework uses a balanced scorecard to align goals, KPIs, accountability, and cross-functional execution with regular review cadences.

- Real-time analytics and employee engagement metrics guide rapid course corrections, sustain gains, and prevent backsliding in performance.

Defining Operational Excellence

Blueprint in hand, you can define operational excellence as a management philosophy that pursues continuous improvement, efficiency, and tight alignment between day-to-day operations and organizational strategy to raise customer satisfaction and overall performance.

You approach it with a customer-centric approach, translating organizational goals into clear standards, measures, and routines.

Rooted in quality control heritage from the 1970s, you apply Lean for waste reduction, Six Sigma for defect minimization, and Kaizen for steady process optimization, integrating them into a coherent system.

Lean cuts waste, Six Sigma reduces defects, Kaizen drives continuous gains—unified into one coherent improvement system.

You standardize work where it adds stability, then improve it through data, feedback, and employee empowerment, ensuring people closest to the work solve problems.

You maintain visual controls and metrics, prioritize flow, and prevent defects at the source, so improvements stick and results compound.

Why Operational Excellence Matters for Leaders

With a clear definition in place, you now need to understand why operational excellence matters for leaders: it turns philosophy into outcomes by giving you a systematic way to align strategy with the daily work that creates customer value, manage risk, and sustain competitive advantage in fast-moving markets.

When you adopt an operational excellence framework, you guide organizational transformation with clear goals, measurable metrics, and disciplined routines that raise efficiency while controlling variability.

You build a culture of continuous improvement, where data informs choices, waste is removed, and customer satisfaction steadily rises.

You also improve resource allocation, directing talent, capital, and time to the highest‑impact work, while strengthening collaboration across functions to reduce friction and accelerate innovation.

- Align strategy to execution

- Raise efficiency and quality

- Improve risk visibility and response

- Focus resources on value

- Enable agile collaboration and innovation

Core Principles and Pillars

Although frameworks vary by industry, operational excellence rests on a consistent set of principles and pillars that you can apply in any organization to convert strategy into reliable performance.

The core principles of operational excellence involve a customer-centric approach, continuous improvement, and employee empowerment, which keep teams focused on value and accountable for results.

Excellence involves Lean thinking to eliminate waste and streamline processes, supported by standardization of processes that reduces variation and stabilizes outputs.

You’ll reinforce these pillars with data-driven decision-making, using real-time insights to target bottlenecks, verify impact, and sustain gains.

Leadership commitment is the glue, because leaders set direction, model behaviors, remove obstacles, and invest in skills.

Together, these elements create a disciplined system that delivers predictable, efficient, and improving operations.

Key Components of a High-Performing System

Even as strategies evolve, a high-performing system rests on a few nonnegotiables that turn intent into dependable results: continuous improvement, strong leadership and culture, customer-centricity, data-driven control, and process standardization.

You build operational excellence by pairing disciplined methods with daily habits that make performance visible, problems solvable, and value unmistakable to customers.

- Use Lean, Six Sigma, and Agile methodologies to eliminate waste, shorten cycles, and stabilize flow.

- Practice data-driven decision-making with real-time KPIs, enabling quick course corrections and predictive control.

- Model leadership that sets direction, removes roadblocks, and develops empowered employees to solve root causes.

- Anchor customer-centricity through feedback loops, journey metrics, and consistent, high-quality service delivery.

- Enforce process standardization to reduce variation across departments, then update standards as improvements stick.

Together, these components create resilient, learning systems.

Building an Operational Excellence Framework

High-performing systems don’t happen by accident; you need a repeatable framework that turns principles into daily routines and measurable outcomes.

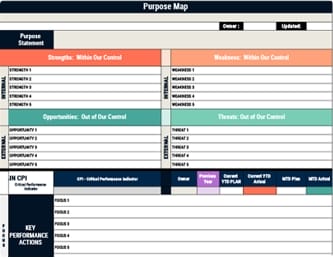

Build your operational excellence framework with a systematic approach that aligns strategy, processes, and people, then translate goals into clear key performance indicators (KPIs) that define success and guide process optimization.

Align strategy, processes, and people, then convert goals into KPIs that drive measurable, continuous optimization.

Map a practical implementation roadmap, sequence initiatives by impact and effort, and guarantee stakeholder engagement across levels so ownership and support are explicit.

Use data-driven decision-making and real-time analytics to monitor performance, reveal bottlenecks, and trigger timely course corrections, while embedding continuous improvement to sustain gains.

Apply Lean principles to remove waste and standardize best practices, and cultivate employee empowerment so teams identify issues and act.

Reinforce accountability with transparent metrics, regular reviews, and clear escalation paths.

Tools and Methodologies: Lean, Six Sigma, Agile

When you’re ready to turn principles into practice, anchor your operational excellence program in proven toolsets—Lean for waste elimination and flow, Six Sigma for variation reduction and defect control, and Agile for rapid, adaptive delivery—then apply each where it fits best.

Use Lean to streamline business processes with value stream mapping and 5S, raising operational efficiency and customer satisfaction. Apply Six Sigma’s DMAIC to stabilize outputs and cut defects, using data to drive process improvement.

Deploy Agile sprints to adapt quickly, improve collaboration, and deliver incremental value. Tie everything together with continuous improvement, Kaizen habits, and clear standards, reinforcing employee engagement and accountability within coherent frameworks and methodologies.

- Map value streams, expose bottlenecks, remove waste

- Standardize work with 5S to sustain gains

- Use DMAIC metrics to control variation

- Run Agile sprints to deliver faster

- Involve teams daily through Kaizen

Real-World Examples and Case Studies

Toolkits matter most when they produce measurable results, so anchor your understanding of Lean, Six Sigma, and Agile by studying how leading companies put them to work and what outcomes they achieved.

Motorola pioneered the Six Sigma methodology in 1986, cutting defects and boosting process visibility, which drove over $16 billion in savings and set a model for operational excellence.

GE scaled these best practices in the 1990s, saving $10 billion while building a culture of continuous improvement and data-driven decisions.

Toyota used Lean manufacturing to halve production costs, streamline operations, accelerate delivery, and lift customer satisfaction.

Dell applied Lean to its supply chain, reducing costs by 20% and speeding shipments.

Spotify adopted Kanban to increase employee engagement, coordinate improvement initiatives, and release features faster.

Measuring Success: KPIs and Continuous Improvement

Although case studies show what’s possible, you measure operational excellence by defining clear KPIs, tracking them routinely, and using the results to drive continuous improvement.

Start by selecting performance indicators that reflect strategy, then apply a balanced scorecard to align financial, customer, internal process, and learning goals.

Use real-time analytics to monitor process efficiency, customer satisfaction, and cost trends, and combine lagging outcomes with leading signals like employee engagement and cycle time.

Conduct regular reviews, close feedback loops quickly, and document improvement efforts to standardize gains and prevent backsliding.

- Define KPIs mapped to strategic outcomes and accountability.

- Track process efficiency, quality defects, and cycle time daily.

- Monitor customer satisfaction and loyalty alongside cost-to-serve.

- Include employee engagement to sustain a proactive culture.

- Review dashboards, act on insights, and verify results.

Frequently Asked Questions

What Is the Operational Excellence Framework?

The operational excellence framework is a structured method you use to optimize processes, reduce waste, and align operations with strategy.

You commit leadership, define customer value, and set KPIs, then streamline workflows with Lean, Six Sigma, and Agile.

You automate finance and routine tasks, embed data-driven decisions, and build feedback loops.

You create an implementation roadmap, engage stakeholders for buy-in, monitor progress, and iteratively refine processes to sustain continuous improvement and measurable results.

What Is a Simple Example of Operational Excellence?

A simple example is Toyota’s Just-in-Time approach: you produce only what’s needed, when it’s needed, with minimal waste.

You standardize tasks, measure cycle times, and adjust schedules based on real demand, so inventory stays lean, errors drop, and flow improves.

You train teams to spot defects early, fix root causes quickly, and share learnings across shifts.

You then review daily metrics, correct deviations, and sustain gains through clear roles and visual controls.

What Are the Three Pillars of Operational Excellence?

The three pillars are process optimization, employee engagement, and customer focus.

You optimize processes using methods like Lean and Six Sigma, eliminating waste, standardizing work, and improving quality.

You engage employees by empowering decisions, encouraging continuous improvement, and building accountability so problems surface early.

You prioritize customers by mapping needs to operations, aligning services and metrics with value and satisfaction.

Together, these pillars create efficient systems that sustain growth and competitive advantage.

What Two Elements Are Required for Building a Proper Operational Excellence Framework?

You need two core elements: measurable structure and engaged execution.

First, define KPIs and a clear implementation roadmap, specifying milestones, owners, and resources, so you can track progress and correct course quickly.

Second, secure cross-level stakeholder involvement and embed feedback loops, ensuring teams surface issues, test improvements, and standardize wins.

You’ll enhance both by leveraging automation and analytics, which streamline processes, reduce errors, and deliver real-time insights that guide continuous refinement.

Conclusion

You can drive operational excellence by aligning daily work to strategy, empowering teams with data, and standardizing improvement through Lean, Six Sigma, and Agile. Start small, fix root causes, and scale what works, because sustained gains beat one-off wins. One compelling statistic: companies that adopt Lean practices report up to 25% productivity improvements within a year. Track KPIs like cycle time, first-pass yield, and customer lead time, then review weekly, so you adjust quickly and compound results.