You can use a Visual Management System to turn complex operations into clear, shared information that everyone can act on, because it translates data into visible cues—boards, dashboards, and signals—that highlight priorities, progress, and problems in real time. By standardizing what’s shown, how it’s updated, and who owns it, you create transparency, faster decisions, and accountability. As you consider which tools and metrics fit your workflows, the next step is deciding how to implement them effectively…

Key Takeaways

- VMS convert complex operational data into clear visual cues, enabling fast, confident decisions and transparent communication across teams.

- Visual tools—displays, controls, and dashboards—make workflows, standards, and KPIs visible, promoting ownership and aligning behaviors to goals.

- Real-time, color-coded dashboards surface deviations instantly, allowing rapid response, root-cause analysis, and reduced handoffs.

- Standardized KPIs, SLAs, and scorecards ensure consistent definitions, transparent performance tracking, and routine reviews that drive improvement.

- Visibility strengthens accountability by linking daily work to outcomes, clarifying expectations, and enabling proactive, data-driven actions.

What Is a Visual Management System and Why It Matters

Clarity is the core promise of a Visual Management System (VMS), a structured way to turn complex operational data into clear visual cues—like color codes, charts, and boards—so you can see performance, spot issues, and act quickly.

You use a VMS to translate key performance indicators into formats anyone can interpret at a glance, improving workplace visibility and enabling faster, more confident decisions.

Rooted in the Toyota Production System, a VMS reinforces transparent communication by putting real-time facts where teams work, which reduces misalignment and supports proactive problem-solving.

A VMS makes facts visible where work happens, cutting misalignment and enabling proactive problem-solving.

When people see results and trends, you strengthen accountability and employee engagement, because expectations and outcomes are visible.

As you sustain this clarity, operational efficiency rises and continuous improvement becomes routine, preventing reactive choices and siloed data.

Core Types of Visual Tools: Displays, Controls, and Dashboards

Foundation tools. You’ll rely on three core categories: visual displays, visual controls, and dashboards.

Use visual displays—like Kanban boards and production charts—to surface workflows and performance metrics at a glance, so teams quickly see progress, constraints, and handoffs, accelerating problem identification before delays grow.

Apply visual controls—such as Andon lights and standardized work charts—to guide behavior, signal status, and enforce standards, which strengthens accountability and reduces variation in daily execution.

Deploy dashboards to integrate key performance indicators (KPIs) into a single view, aligning priorities and enabling data-driven decisions that improve operational efficiency.

When you make results visible, you promote transparency and team ownership, because everyone can compare current performance to targets, discuss gaps objectively, and escalate issues with shared context and clear next steps.

Real-Time Data, Color Coding, and Interactive Displays

Although visual tools can work with static snapshots, you reveal their full value by streaming real-time data into color-coded, interactive displays that surface what’s happening now, show where attention is needed, and let teams drill into causes without leaving the screen.

In visual management systems, you use real-time data to expose operational deviations as they occur, then apply color coding so status is unambiguous: red signals an issue, yellow flags risk, and green confirms flow.

With interactive displays, you tap, filter, and zoom to trace where and why a problem started, which accelerates collaborative problem-solving and reduces handoffs.

Shared dashboards enhance communication and transparency, break down silos, and align actions across shifts. By shortening detection-to-response time, you cultivate an agile culture that acts decisively.

Tracking Goals With KPIS, SLAS, Scorecards, and Metrics

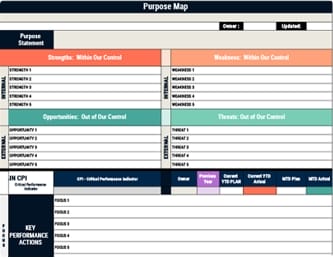

When you track goals in a visual management system, you translate strategy into measurable signals by defining KPIs that quantify success, setting SLAs that specify service expectations, and organizing both into scorecards and metrics dashboards that make performance visible and actionable.

You start by mapping objectives to precise KPIs, selecting units, targets, and thresholds that reflect desired performance, then link SLAs to customer-facing commitments so teams know the standard they must meet.

Next, build scorecards that group related metrics, highlight variances, and show trend lines for tracking progress over time. Use dashboards to consolidate real-time indicators, surface exceptions, and prompt timely reviews.

Build scorecards to track trends, spotlight variances, and use dashboards for real-time exceptions and timely reviews.

Finally, standardize definitions and data sources to guarantee transparency and accountability, enabling consistent routines that drive operational excellence.

Benefits: Communication, Accountability, Speed, Engagement, and Decisions

Because visual management systems turn raw data into shared, actionable visuals, they strengthen how your teams communicate, own outcomes, move faster, stay engaged, and decide with confidence.

You improve communication because complex information becomes clear at a glance, reducing rework and misalignment across functions. With real-time visibility into key performance indicators, accountability rises, since everyone can see progress, owners, and gaps tied to goals.

You gain speed by spotting bottlenecks early, triggering faster responses that protect operational efficiency. Engagement grows as transparency recognizes contributions and connects daily work to outcomes, reinforcing purpose and participation.

Finally, decisions improve because leaders and frontline teams access timely, relevant data, compare trends, and prioritize risks, enabling proactive actions that stabilize performance and sustain momentum.

Step-by-Step Implementation and Best Practices

Strong results from visual management only stick if you build the system methodically, so start by mapping current workflows to pinpoint where visibility breaks down.

Then engage the people who run those processes to define what they need to see at a glance. Align your implementation with organizational goals, involve stakeholders to select fit-for-purpose visual tools, and document clear expectations for maintaining, updating, and auditing boards and dashboards.

Engage process owners, align with goals, choose fit-for-purpose visuals, and set clear maintenance and audit standards.

Launch pilot programs in controlled areas to validate assumptions, collect employee feedback, and refine standards before scaling.

Run role-specific training sessions that show how visual management practices guide daily decisions, escalation, and problem-solving.

Establish a cadence for reviews, cross-check data accuracy at the source, and use findings to drive continuous improvement, retiring clutter and embedding simple, actionable visuals.

Frequently Asked Questions

What Is the 1 3 10 Rule in Visual Management?

The 1-3-10 rule states you should see critical information within 1 minute, access supporting details within 3 minutes, and fully understand the situation within 10 minutes.

You design boards, dashboards, or displays so key metrics, status, and alerts pop immediately, drill-downs are obvious, and explanations are clear.

You reduce search and interpretation time, enable faster decisions, and promote accountability, because everyone can grasp what’s happening and what action’s required without delays.

What Are the 4 Guiding Principles of Visual Management?

Like a compass guiding a team, the four guiding principles are clarity, alignment, engagement, and responsiveness.

You present information simply and visibly for quick understanding. You link visuals to goals so priorities stay consistent. You involve employees in creating and updating boards to build ownership. You keep data current to trigger timely action.

Together, these principles reduce ambiguity, improve coordination, and help you spot issues fast, then adjust decisions with confidence.

What Is the Purpose of a Visual Management System?

The purpose of a visual management system is to turn complex operational data into clear, real-time information you can act on quickly.

You use it to track key performance indicators, spot trends, and detect issues early, which reduces delays and guesswork.

It clarifies expectations, supports accountability, and aligns daily work with strategic goals.

You facilitate structured team huddles, guide problem-solving, and sustain continuous improvement, strengthening engagement and overall performance across your operations.

What Are the 5 C’s of Lean Manufacturing?

The 5 C’s of Lean Manufacturing are Clear, Concise, Consistent, Compliant, and Continuous.

You make communication clear with visual cues and unambiguous instructions, keep information concise to reduce clutter and speed decisions, and enforce consistency so processes and standards don’t vary.

You stay compliant by adhering to regulations and internal requirements, then drive continuous improvement through regular reviews, problem-solving, and standard updates, ensuring safety, quality, and reliable performance across operations.

Conclusion

Wrap up by committing to visual management now, because you’ll align goals, track KPIs, and act faster using clear dashboards, color cues, and real-time displays. You’ll set standards, highlight gaps, and guide teams toward fixes before issues grow, like a telegraph speeding news across the shop floor. Start small, define ownership, and iterate, ensuring data is timely, accurate, and visible. With disciplined reviews and simple rules, you’ll build accountability, sustain engagement, and make better decisions, consistently and repeatably.