You don’t need a massive overhaul to gain traction—operational excellence software lets you tighten processes with targeted, practical steps. You’ll use real-time metrics to spot bottlenecks, enforce standardized workflows to cut variation, and apply automation to remove manual handoffs, while collaboration tools keep teams aligned. With integrations pulling data across systems, you can track KPIs, reduce waste through value stream insights, and adapt quickly as demands shift, which raises a critical question about choosing the right platform.

Key Takeaways

- Real-time dashboards expose bottlenecks, track cycle times, and guide data-driven decisions to boost throughput and quality.

- Automation eliminates repetitive tasks, reduces errors, and speeds handoffs across standardized workflows.

- Built-in Lean/Six Sigma tools support waste reduction, root-cause analysis, and continuous improvement at scale.

- Collaboration and change management features centralize communication, accelerate issue resolution, and sustain adoption.

- KPI management and coaching embed feedback loops, recalibrate targets, and align teams to measurable performance goals.

What Is Operational Excellence Software

Operational excellence software is a suite of digital tools that helps you systematically improve how work gets done by streamlining processes, reducing waste, and cutting costs across departments and industries.

You use operational excellence software to standardize workflows, apply Lean and Six Sigma practices, and streamline operations with automation, collaboration, and clear ownership.

It gives you performance metrics and analytics that reveal bottlenecks, quantify defects, and track cycle times, so you can reduce waste and target improvements with evidence.

Its adaptability helps you adjust processes as conditions change, while a flexible and scalable architecture supports teams of any size.

Why It Matters Across Industries

Even as industries differ in products and regulations, they share the same mandate: do more, faster, and with fewer errors, and that’s where operational excellence software delivers outsized value.

You use software solutions to streamline processes, automate routine work, and cut delays, which supports higher productivity and reliable delivery across manufacturing, healthcare, logistics, and services.

With clear workflows and metrics, you identify waste, allocate resources wisely, and drive continuous improvement, helping teams adapt to changing business demands while maintaining quality.

Analytics highlight root causes, so you act quickly, prevent rework, and enhance customer satisfaction through predictable outcomes and shorter cycle times.

By standardizing best practices, you increase employee engagement, reduce ambiguity, and sustain Continuous Operational Excellence across departments and sites.

- Align goals, measures, and actions for consistent execution

- Surface bottlenecks early with real-time visibility

- Scale improvements enterprise-wide without adding complexity

Core Features That Maximize Performance

While tools vary by vendor, the core features that maximize performance share a common purpose: give you timely insight, reduce friction, and standardize excellence across teams.

In Operational Excellence Software, real-time performance metrics show where processes lag, helping you target waste and align work with strategic goals. Use automation features to remove repetitive steps, cut errors, and free your team for higher-value analysis and decision-making.

Rely on collaboration tools to centralize communication, document actions, and accelerate problem-solving across functions. Apply quality management to enforce standards, track defects, and sustain customer satisfaction.

Choose adaptability features that scale as volumes grow or requirements change, so improvements hold under pressure. Together, these capabilities drive continuous improvement by linking daily execution to measurable outcomes and consistent behaviors.

Integrations, Automation, and Data Analytics

Because excellence depends on what your systems can see and do together, integrations, automation, and data analytics form the backbone of high-performing operations.

Excellence emerges when systems see and act together—integrations, automation, and analytics powering performance.

You’ll connect existing tools through Integration to enable real-time sharing, so teams collaborate faster, workflows synchronize, and delays shrink. Automation removes manual steps, cutting errors and lifting productivity by up to 30%, while standardized rules keep outputs consistent.

Data Analytics tracks Key Performance metrics and uses predictive models to flag bottlenecks early, letting you adjust resources before issues escalate and aligning outcomes with Customer Needs.

- Unify data flows across departments to improve visibility, shorten handoffs, and accelerate Operational decisions.

- Automate repetitive tasks to raise Performance, reduce rework, and protect quality.

- Apply analytics and forecasting to refine plans, balance capacity, and sustain Excellence.

Value Stream Management and Waste Reduction

If you want to cut lead time and boost throughput without guessing, start by applying Value Stream Management (VSM) to visualize how materials and information actually move from request to delivery.

Map each step, measure touch time and delays, then target waste reduction across the seven wastes—overproduction, waiting, transport, extra processing, inventory, motion, and defects—which often consume most cycle time.

Use value stream management to streamline processes, remove nonvalue activities, and realign work with customer demand.

Quantify gains by redesigning flow, balancing workloads, and error-proofing handoffs, which can cut lead times by up to 50% and raise productivity by as much as 30%.

Build continuous improvement into daily routines so performance remains aligned with business goals and changing business needs, helping you Achieve Operational Excellence.

Real-Time KPI Tracking and Reporting

After streamlining flow with value stream management, lock in gains by tracking the right key performance indicators in real time so you can see what’s working and fix what’s not without waiting for end‑of‑week reports.

With real-time KPI tracking, you monitor performance metrics instantly, reduce data collection effort through automated reporting tools, and shift time toward analysis and action. You gain operational efficiency by spotting trends as they emerge, addressing bottlenecks quickly, and coordinating responses across teams.

Continuous visibility builds accountability, since results are transparent and comparable. Integrated dashboards provide an all-encompassing view of performance across departments, linking processes and outcomes so you manage exceptions before they escalate and sustain operational agility.

- Define a small, critical KPI set, then instrument data capture.

- Standardize thresholds, alerts, and owners.

- Review variance daily, document actions, and follow up.

How to Choose the Right Platform for Your Organization

Where should you start when choosing an operational excellence platform? Begin by naming your top pain points and improvement goals, then confirm the Operational Excellence Software can streamline operational processes that matter most.

Involve frontline and leadership voices early; structured employee feedback uncovers must‑have features and usability issues you might miss. Rigorously assess software accessibility on web and mobile, since frictionless access drives adoption and data quality.

Prioritize scalability so the system grows with volumes, users, and workflows while adapting to market conditions without costly rebuilds.

Compare training and support resources, including onboarding, role-based learning, and responsive help desks, to shorten time to value.

Finally, validate integrations, security, and configurability through live demos and trials, ensuring you’re choosing the right platform for long-term performance.

Implementation Roadmap and Change Management

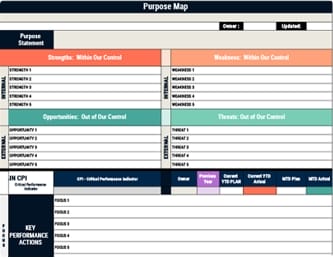

Though every organization’s path looks different, your implementation roadmap should start with a clear baseline: map current processes, document pain points, and select a concise set of KPIs that will prove whether the software is improving safety, quality, speed, and cost.

From there, define key performance indicators, align goals, and secure stakeholder engagement with clear messaging about benefits and roles.

Plan a phased rollout to reduce risk, collect lessons, and scale what works. Provide thorough training, job aids, and support so users can apply the operational excellence software in daily work.

Establish feedback loops to track adoption, surface issues, and guide timely adjustments. Maintain disciplined change management with visible sponsorship, consistent communication, and measurable outcomes tied to the roadmap.

- Prioritize quick wins that validate value

- Calibrate KPIs as processes mature

- Embed coaching into daily routines

Frequently Asked Questions

What Is Operational Excellence Software?

Operational excellence software is a platform you use to streamline processes, reduce waste, and improve quality across your operations.

You’ll map workflows, standardize tasks, and apply Lean and Six Sigma tools, while dashboards track KPIs and surface bottlenecks for data-driven decisions.

Automation reduces manual errors and cycle times, integrations align teams and resources, and guided improvement projects sustain gains, so you systematically deliver better outcomes, lower costs, and higher customer satisfaction.

What Are the Three Pillars of Operational Excellence?

The three pillars are people, processes, and technology.

Like a three-legged stool, you need all three balanced. You develop people through clear roles, training, and engagement, so they solve problems and collaborate.

You design processes that are documented, standardized, and continuously improved, reducing variation and waste.

You deploy technology that automates routine work, provides data visibility, and augments decision-making, ensuring people and processes operate efficiently and adapt to changing demands.

What Is the Operational Excellence Performance System?

The operational excellence performance system is a structured, continuous improvement approach you use to streamline processes and boost outcomes.

You set clear KPIs, map workflows, analyze data, and remove waste using Lean and Six Sigma methods, then standardize best practices.

You review performance regularly, automate repetitive tasks to reduce errors, and build accountability through visible metrics and owner roles.

You’ll increase efficiency, lower costs, improve quality, and sustain gains through disciplined governance and training.

Which Tools Do You Need to Develop in Order to Exploit Complexity to Enable Operational Excellence and Create a Unique Customer Experience?

You need value stream mapping, workflow automation (RPA), continuous improvement trackers, cross-functional collaboration hubs, and customer analytics.

Picture a pit crew: each tool’s a wrench, sensor, or radio, letting you tune performance in real time. You map bottlenecks, automate repetitive steps, capture feedback, coordinate fixes, and personalize experiences from data.

Layer governance dashboards, alerting, and A/B testing, so you exploit complexity, reduce waste, and deliver distinctive, consistent customer journeys.

Conclusion

By choosing the right operational excellence software, you’ll align strategy, processes, and people, then prove impact with real-time KPIs and continuous improvement loops. Start with clear goals, map value streams, integrate key systems, and automate repeatable work, ensuring data quality and governance. Pilot, iterate, and scale with disciplined change management and training. Done well, you’ll cut waste, improve reliability, and adapt faster—turning chaos into clarity at the speed of light, while building a durable, measurable performance engine.