If you could flip a switch and make your factory faster, safer, and smarter overnight, you’d start by mastering manufacturing excellence. You’ll use lean principles to remove waste, align teams around safety, quality, yield, and productivity, and apply real-time analytics to turn data into action. You’ll connect people and machines with simple digital tools, measure what matters with clear KPIs, and build a resilient supply chain. The only catch is knowing where to start—and what to do next.

Key Takeaways

- Manufacturing excellence blends Lean, continuous improvement culture, and digital tools to eliminate waste, stabilize processes, and align leadership with frontline empowerment.

- Anchor operations on safety, quality, yield, and productivity, reinforced by continuous improvement loops and standardized best practices.

- Measure performance with OEE, First Pass Yield, and inventory turnover, using real-time MES analytics, clear targets, and escalation rules.

- Implement via process mapping, 5S, visual controls, standard work, and PDCA/DMAIC cycles, empowered by Industry 4.0 data and digital work instructions.

- Future-proof with AI, IoT, and modular automation, linking sustainability to efficiency to deliver 20–30% cost savings and competitive advantage.

What Is Manufacturing Excellence?

Manufacturing excellence is a systematic, enterprise-wide way of running operations that blends Lean principles, a continuous improvement culture, and modern digital tools to deliver world-class performance consistently, not just in one-off projects.

You use it as a holistic management approach that aligns leadership behavior, capability development, and employee empowerment to raise operational efficiency and eliminate waste across value streams.

By embedding Lean principles into daily work, you build reliable processes that hit quality standards, protect safety, and increase productivity.

You also connect an integrated supply chain, so materials, information, and decisions flow without delays or defects.

While high capital costs, legacy systems, and skill gaps can slow adoption, you reduce risk by prioritizing digital tools with fast payback, training frontline teams, and sequencing improvements.

Core Principles of Manufacturing Excellence

Four interconnected principles anchor manufacturing excellence, and you should apply them together rather than as isolated initiatives.

First, drive continuous improvement through Lean manufacturing methods that expose and remove waste, using daily Kaizen, Gemba walks, and standard work to stabilize manufacturing processes and raise productivity and efficiency.

Second, embed quality control with a right-first-time mindset, applying SPC, mistake-proofing, and digital twins to prevent defects rather than detect them late.

Third, strengthen employee empowerment by enabling quality circles, visual management, and team-based scorecards so frontline teams solve problems at the source.

Fourth, build an integrated supply chain that synchronizes demand signals, tracks supplier performance with real-time data, and coordinates replenishment to cut lead times and variability, reinforcing waste reduction and operational excellence.

The Four Pillars: Safety, Quality, Yield, Productivity

A practical framework for operational excellence starts with the Four Pillars—Safety, Quality, Yield, and Productivity—which you should treat as a single system rather than disconnected metrics.

Prioritize safety as the non-negotiable baseline, using IoT-enabled PPE monitoring to prevent incidents and sustain operational performance.

Build quality into the process with inline defect analytics, catching issues in real time so rework and waste don’t cascade downstream.

Monitor yield rigorously with batch-wise yield tracking, linking materials, methods, and equipment to root causes, then standardizing the best settings.

Elevate productivity by combining collaborative robots with digital work instructions, which stabilize cycle times, reduce variability, and speed changeovers.

Tie these practices together through continuous improvement loops, reviewing data daily, acting quickly, and standardizing gains to lock in results.

Common Challenges and How to Overcome Them

With the pillars in place, you’ll quickly encounter practical obstacles that determine whether the system takes root or stalls, so address them methodically from day one.

Start by framing Lean manufacturing as a staged journey, not an all-or-nothing leap, to manage operational costs and high capital outlays; pilot digital solutions where payback is shortest, then reinvest savings.

Reduce cultural resistance by involving teams in standard setting, explaining why changes matter, and recognizing wins to build employee engagement.

Close skill gaps through targeted training, job aids, and mentoring, so continuous improvement becomes routine work.

Tackle fragmented systems by integrating technologies with modular, interoperable platforms that solve specific pain points.

Align incentives using clear performance metrics, shared goals, and cross-functional cadences to surface improvement opportunities consistently.

Measuring Excellence: KPIs and Real-Time Analytics

Even as lean practices mature, excellence depends on what you measure and how quickly you act on it, so anchor your system in a concise set of KPIs and real-time visibility.

Track Overall Equipment Effectiveness (OEE), First Pass Yield, and inventory turnover to gauge operational performance, then use real-time analytics from MES and cloud dashboards to expose bottlenecks, deviations, and waste as they occur.

Track OEE, First Pass Yield, and inventory turnover, using real-time MES dashboards to reveal bottlenecks and waste instantly.

Define clear targets, owners, and escalation rules, so frontline teams respond within minutes, not days.

Tie KPIs to continuous improvement by linking alerts to root-cause routines and standard work updates.

Strengthen process capability to cut defects and warranty claims, while layout and flow changes lift margins.

Use objective data to build a proactive culture and guide strategic decisions across lean operations and manufacturing excellence.

Value Realization: From Activity to Business Impact

Because lean activity only matters when it moves the numbers that run the business, value realization focuses you on translating daily operations into measurable outcomes like lower cost per unit, higher First Pass Yield, fewer warranty claims, and stronger customer satisfaction.

You connect operational activities to business impact by tying Lean principles and continuous improvement to clear Key Performance Indicators (KPIs), such as OEE and FPY, then verifying gains with real-time analytics and cloud dashboards.

When production efficiency rises and waste elimination removes nonvalue tasks, you strengthen process capabilities that cut defects and have reduced warranty claims by 25%.

Prioritize EBITDA-linked levers—layout optimization, cycle-time reduction, and right-first-time quality—and sustain results through employee engagement, since trained frontline teams double retention and stabilize performance.

Implementation Playbook for Lean and Continuous Improvement

How do you turn Lean from a concept into daily practice that moves your numbers? Start by mapping current processes and identifying bottlenecks, delays, and defects, then quantify the baseline to target eliminating waste.

Translate Lean Manufacturing principles and the Toyota Production System into standard work, visual controls, and 5S so teams see problems quickly and act.

Turn Lean into action: standard work, visual controls, and 5S that reveal problems fast.

Define Key Performance Indicators (KPIs) that matter—Overall Equipment Effectiveness (OEE), First Pass Yield, lead time, and scrap—then review them daily at tiered huddles to drive process improvement.

Use the PDCA cycle and DMAIC to plan experiments, execute changes, verify results, and lock in gains with control plans.

Build a culture of continuous improvement through Kaizen events, routine coaching, and clear communication, sustaining employee engagement with training, recognition, and transparent results.

Empowering People With Technology: Bridging Humans and Machines

Why bridge humans and machines now? You’ll achieve manufacturing excellence faster when you treat technology as an enabler for human workers, not a replacement.

Use Industry 4.0 tools to deliver real-time data at the point of work, so operators see issues instantly, follow interactive instructions, and reduce errors. With platforms like Tulip, start empowering employees to build tailored apps that fit unique workflows, boosting engagement and ownership.

Integrate these apps with connected devices to streamline operations, capturing timestamps, counts, and quality checks automatically, while guiding decisions with live dashboards.

Standardize best practices, then iterate, using data to target bottlenecks and confirm operational improvements. Build feedback loops where teams adjust work instructions, update forms, and refine triggers, reinforcing continuous improvement and accountability across the shop floor.

Future-Proofing Through Innovation and Sustainability

Although market conditions will keep shifting, you can future-proof operations by pairing innovation with sustainability so every improvement strengthens resilience, cuts cost, and meets rising stakeholder expectations.

Use continuous improvement to tie sustainable choices to measurable gains in operational efficiency, prioritizing energy-efficient equipment, waste reduction, and smart maintenance.

Apply advanced technologies—AI, IoT, and automation—to boost productivity by up to 30%, while aligning with environmental consciousness that’s shaping demand and regulation.

1) Quantify value: model cost savings of 20–30% from energy-efficient upgrades and waste reduction, then track yield, uptime, and emissions to verify results.

2) Build adaptability: design processes that flex with market fluctuations, integrating scalable data platforms and modular automation.

3) Strengthen the competitive edge: market sustainable innovation, leveraging consumer willingness to pay more and long-term stock performance benefits.

Frequently Asked Questions

What Are the 5 C’s of Lean Manufacturing?

The 5 C’s are Sort, Set in Order, Shine, Standardize, and Sustain.

You first remove unnecessary items to clear clutter, then arrange tools for fast access and smooth flow.

Next, clean and inspect regularly to maintain safety and quality.

You lock in the gains with clear procedures and visual controls, and finally, you build discipline through training, audits, and leadership support so the standards persist and continuous improvement becomes routine.

What Are the 4 P’s of Lean Manufacturing?

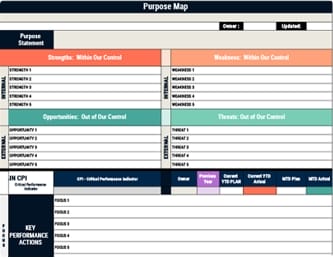

The 4 P’s of lean manufacturing are Purpose, Process, People, and Performance.

You define Purpose by clarifying customer value and aligning goals to deliver it.

You design Process by mapping workflows, removing waste, and improving flow.

You engage People by empowering teams, standardizing work, and building continuous improvement habits.

You track Performance with metrics like OEE and FPY, then review gaps, prioritize countermeasures, and sustain gains through visual management and disciplined problem-solving.

What Are the 5 Core Principles of Lean Manufacturing?

Right out of the gate, you’ll apply five core Lean principles: specify value from the customer’s view, identify the value stream to expose waste, create flow so work moves smoothly without interruptions, establish pull so production matches real demand, and pursue perfection through continuous improvement.

You’ll map processes, remove non-value steps, balance workloads, and standardize tasks, then use feedback loops and problem-solving to sustain gains, reduce cost, improve quality, and boost customer satisfaction.

What Are the 5 Key Principles of Continuous Improvement?

The five key principles are: define value from your customer’s perspective, map the value stream to expose waste, create flow so value-adding steps move smoothly, establish pull so work happens only when needed, and pursue perfection through ongoing improvement.

You identify what customers truly need, visualize every process step, remove non-value activities, balance and streamline handoffs, then iteratively refine standards, metrics, and problem-solving so quality rises, costs fall, and cycle times shrink.

Conclusion

You’ll chase Manufacturing Excellence like it’s a finish line, yet the punchline is simple: there isn’t one. You standardize, measure, and improve, then repeat, because stability invites better data, and better data exposes new waste. You’ll align safety, quality, yield, and productivity, connect people with real-time analytics, and translate activities into business impact. When constraints shift, you’ll adapt through disciplined experiments, not guesswork, and you’ll sustain gains by empowering teams, digitizing processes, and auditing relentlessly to keep drift from returning.