Go see the work, ask why it happens, show respect as you learn. You’ll visit the real place where value is created, observe the process against standard work, and ask open questions that surface causes without blame. You’ll map the flow, note deviations, and capture time-stamped data, photos, and quotes. Then you’ll assign owners and timelines for small experiments, connect findings to governance rhythms, and, with a few precise checklists, you’ll spot what most reviews miss…

Key Takeaways

- Go to the actual workplace (Gemba) to observe real work, compare to standard work, and see deviations without judgment.

- Engage frontline workers; ask open-ended “why” questions to uncover root causes across sequence, timing, tools, and handoffs.

- Follow the product/service flow; trace bottlenecks, stalls, workarounds, and approvals across linked stations.

- Capture evidence rigorously with timestamps, photos, and simple metrics; avoid assumptions and link symptoms to plausible drivers.

- Convert findings into actions using PDCA/Kaizen, with owners, timelines, and follow-up tied to safety, quality, delivery, cost, or morale.

What Is a Gemba Walk and Why It Matters

Why leave your office to solve problems? A Gemba Walk takes you to the “real place” where value is created—factory lines, service counters, labs, or digital operations—so you can see work as it actually happens. Instead of relying on dashboards or secondhand summaries, you observe processes, spot waste, and confirm facts directly at the source. You talk with people doing the work to understand conditions, constraints, and opportunities, then align what you see with business goals. A Gemba Walk matters because firsthand observation exposes issues that reports miss, helping you separate signal from noise. You plan the route, choose focus areas, and document what you learn, then turn insights into targeted actions, owners, and timelines. With disciplined follow-up, your walk produces measurable improvements. Integrating insights with process optimization and clear roles ensures issues found at the source translate into efficient, accountable improvements.

Core Principles: Go See, Ask Why, Show Respect

How do you turn a walk into real improvement? Start with Go See: go to the Gemba—the shop floor, service area, or core production area—and observe the actual process, not the people. Stand where the work happens, map the flow, and compare what you see to standard work, noting deviations, bottlenecks, and waste without judgment. Engage frontline workers directly, since they’re closest to the facts and can clarify why steps occur as they do.

Next, Ask Why with open-ended questions that expose causes rather than symptoms; probe sequence, timing, tools, and handoffs, and listen more than you speak.

Finally, Show Respect by practicing humility, avoiding blame, and inviting ideas. Document findings, assign clear owners, define timelines, and follow up to convert observations into actionable improvements. To sustain improvements, connect each observation to aligned OKRs and integrate it into governance rhythms for continuous progress tracking.

Benefits You Can Expect From Regular Gemba Walks

What makes regular Gemba walks valuable is the direct line they create between observed reality and targeted improvement, giving you firsthand insight into actual work conditions while strengthening communication with the people doing the work. When you stand where value is created, you see constraints, handoffs, and workarounds that reports miss, so you can act on facts instead of assumptions. You also build engagement by inviting front-line staff to explain obstacles, suggest fixes, and validate what works. In aligned organizations, Gemba insights more effectively translate into measurable improvements because they reinforce clear communication and shared values that connect daily work to strategic goals. Through direct observation, you spot waste like excess inventory, unnecessary motion, and defects, then standardize best practices that align with Lean and Six Sigma. Over time, routine visits promote accountability because you plan checks, gather simple data, and follow up with measurable actions, which sustains continuous improvement and learning.

Preparing With Purpose: Objectives, Data, and Route

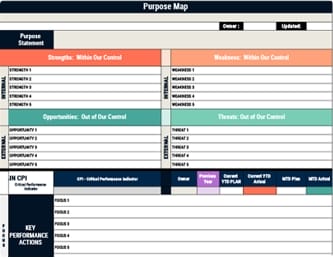

Grounded benefits become real only when you prepare with purpose, so start by setting clear objectives that name the processes, areas, or issues you intend to observe and improve. Define what good looks like, note suspected pain points, and connect goals to safety, quality, delivery, cost, or morale so you can judge outcomes later.

Next, assemble relevant data before you go: recent metrics, process documentation, standard work, value stream maps, and any change notes, which help you distinguish normal variation from true problems. Map your route to follow the product or service flow, moving through linked workstations in a logical sequence to see handoffs and constraints. Align your plan with enabling conditions and standard operating procedures to focus observation on continuous improvement opportunities. To keep teams informed and motivated during the walk and follow-up, establish continuous communication and feedback loops that reinforce shared objectives and accelerate improvements.

Checklists and Questions to Guide Observation

Why rely on memory when a structured checklist and pointed questions can keep your Gemba Walk focused on facts, not assumptions? Build a checklist that mirrors your purpose, then sequence it from safety and customer impact to process steps and results, so you consistently capture what matters. Note the standard, the observed condition, the gap, and the evidence, using photos or timestamps to anchor findings. Use color-coded indicators like green for normal and red for problems to enable quick, intuitive assessments that align with visual management best practices. Ask questions that target process, not people: What’s the standard here, and where’s it visible? What variation do you see, and how often? What makes the right way hard? What signal triggers help, and who responds? What defects escape this step, and how do you know? Use a digital platform like Moxo to convert observations into owners, due dates, and real-time updates.

On the Floor: Observing Flow, Standardization, and Waste

How do you make the most of your time on the floor? Start by tracing the product’s path step by step, noting where work stalls, piles up, or doubles back, and compare what you see to the SOPs to spot deviations. Watch for bottlenecks at handoffs, changeovers, and approvals, then look for ad‑hoc workarounds that bypass standard work and introduce variation. Incorporate the 1-3-10 rule to ensure issues are visually identifiable within seconds and that required actions and owners are immediately clear. Systematically capture waste: overproduction, waiting, unnecessary motion, extra processing, transport, inventory, and defects. Log timestamps to quantify delays, take annotated photos or short videos with consent, and record how each waste instance affects throughput, rework, and quality.

Use a structured observation sheet to tie findings to corrective actions, such as revising standard work, balancing tasks, tightening layout, clarifying triggers, or adjusting inventory buffers.

Engaging Employees With Empathy and Open Dialogue

Curiously, the most effective Gemba walks start with sincere conversations, not clipboards, because you’ll learn more by asking people to explain their work than by inspecting from a distance. Approach each station with empathy, introduce yourself, and set a blame-free tone, then invite people to describe what’s hard, what’s going well, and what they’d change.

Use open-ended prompts—“What slows you down?” “When does this process break?”—so you uncover root causes rather than symptoms. Tailor questions to roles, since operators, technicians, and support staff see different constraints and opportunities, and listen for conditions, handoffs, and signals that shape their day.

Reinforce psychological safety by thanking candor, reflecting back what you heard, and clarifying next steps, including owners, timelines, and measurable outcomes for follow-up actions. In parallel, surface and visualize issues with simple Andon systems so teams get real-time feedback and can respond quickly, reinforcing transparency and continuous improvement.

Capturing Evidence and Data for Analysis

So, as you shift from conversation to analysis, capture evidence in a disciplined way that blends what people say with what the process shows, recording both qualitative observations and quantitative measures like cycle times, defect rates, and inventory levels. Use photos, short videos, and structured digital forms to log each observation with clear what, where, when, and suspected causes, ensuring details are time-stamped and traceable. Translate raw notes into concise entries that connect symptoms to possible drivers, avoiding assumptions you can’t support with data.

After the walk, organize data with value stream maps to reveal flow constraints, then apply cause-and-effect diagrams and 5 Whys to probe likely roots. Use a digital platform like Moxo to create auditable records, enable AI-driven data extraction, and provide real-time updates on evidence-based progress. To sustain transparency and accountability, establish a routine for regularly reporting outcomes so stakeholders can see progress and adjust actions based on the collected evidence.

From Findings to Action: Kaizen, PDCA, and Ownership

Why let insights sit idle when you can convert them into disciplined improvement? Move from observation to action using Kaizen and PDCA, applying small, targeted experiments alongside system-level fixes. Translate your gemba findings into clear problems, define the gap, and choose a fitting method: run daily Kaizen for point issues, or apply a robust problem-solving process, such as the Toyota TBP eight-step method, for complex, cross-functional gaps. In parallel, strengthen your operating rhythm with integrated business planning to align data, cadence, and cross-functional decisions so improvements scale without silos. Map the value stream to reveal flow, delays, and information handoffs, then redesign the system to remove waste and expose problems early. Build standardized work from the improved method, ensuring repeatability and training. Cycle PDCA relentlessly—plan a change, try it, check the results, and act to lock gains. Assign ownership, timelines, and follow-up cadence to sustain momentum.

Tools, Templates, and Digital Aids to Sustain Improvements

With PDCA cycles underway and owners assigned, you now need tools that make improvements stick by turning observations into structured, auditable work. Start by standardizing your Gemba walk with digital templates that guide evidence capture, enforce required fields, and auto-create follow-up tasks with due dates and assignees. Use Moxo Magic Links to let suppliers or partners upload photos, videos, and documents without a login, simplifying external proof collection while keeping everything in one workflow. Deploy AI Agents to scan submissions for compliance, answer clarifying questions, and extract structured data from forms, reducing manual review and errors. Monitor dashboards for completion rates, average resolution times, and recurring issues, then adjust standards. Protect records with SSO/SAML, RBAC, audit trails, and versioning. As you scale, align strategy and execution with measurable OKRs to ensure cross-functional teams stay focused on unified objectives, mirroring how leaders like Tesla used strategic alignment to turn plans into results.

Frequently Asked Questions

How Do Remote or Hybrid Teams Conduct Effective Virtual Gemba Walks?

Schedule regular video “go-and-see” sessions, share screens or live process feeds, and focus on the actual workflow, not reports. Define a clear purpose, standard agenda, and roles, then use a checklist to observe handoffs, delays, errors, and workload. Ask open, nonjudgmental questions, capture evidence with recordings or annotated screenshots, and log actions in a shared tracker. Close with owners, deadlines, and follow-up dates, then verify changes with quick, targeted revisits.

What Metrics Quantify Leadership Behavior Change From Gemba Practices?

Like a 56K modem, you measure leadership behavior change through concrete, repeated signals: track frequency and duration of gemba visits, ratio of observation-to-intervention, and percent of actions closed on time. Monitor psychological safety scores, employee suggestion rates, and response cycle time from issue identification to root-cause fix. Add coachable moments per walk, cross-functional participation rate, and audit findings rework. Finally, link these to outcome shifts: defect rate, lead time, and turnover.

How Often Should Executives Versus Frontline Leaders Participate?

Executives should participate monthly, ideally one to two hours per site, to set direction, sense systemic issues, and remove cross-functional barriers.

Frontline leaders should participate daily or several times per week, using brief, structured walks to coach standards, verify problem-solving, and escalate risks quickly.

You should align cadence with process volatility and maturity, increase frequency during major changes or instability, and always close the loop by tracking actions, publishing outcomes, and measuring impact.

How Do You Handle Union Considerations During Gemba Engagements?

You handle union considerations by engaging early with union leaders, clarifying purposes, scope, and boundaries, and aligning with contract language. You brief stewards, invite participation, and avoid individual performance critiques, focusing on processes, safety, and waste. You obtain consent before observations, respect work rules, and schedule walks to minimize disruption. You document findings transparently, share data with joint committees, and agree on follow-up actions, ensuring changes use established grievance and bargaining protocols.

What Legal/Privacy Constraints Apply to Recording During Gemba Walks?

About 16 states require two-party consent for recordings, so you must verify consent laws first, then secure written consent from employees and contractors.

You can’t record audio in areas with a reasonable expectation of privacy, and you must avoid capturing protected health or personal data. Post clear notices, limit recording to business purposes, restrict access, encrypt storage, set retention limits, and coordinate with legal, HR, and union reps to align policy and practice.

Conclusion

You’re ready to walk the gemba with purpose: set clear objectives, review data, choose a route, and use open questions to see work as it happens. Like a lens that sharpens focus, you’ll map flow, spot deviations from standard work, and engage people respectfully to surface real causes. Capture time-stamped evidence, assign owners, and run targeted Kaizen using PDCA. Finally, anchor improvements in governance rhythms so learning sticks, performance becomes visible, and problems don’t hide between visits.