You move from rules to reasons, from checklists to choices, from oversight to ownership when you treat safety and quality as shared work. You set clear expectations, model visible leadership, and align incentives with outcomes, not paperwork. You coach peers to speak up, use digital tools to surface risks, and tie training to real tasks. You measure what matters and close feedback loops quickly, because the next step is where commitment gets tested—every day.

Key Takeaways

- Shift from checkbox compliance to shared ownership by embedding clear expectations, peer accountability, and outcome-focused routines in daily work.

- Leaders model non-negotiable standards through visible safety walks, practical questions, PPE use, and recognition of issue-spotters.

- Empower employees with task-aligned training, microlearning, simulations, and psychological safety to reward reporting and near-miss insights.

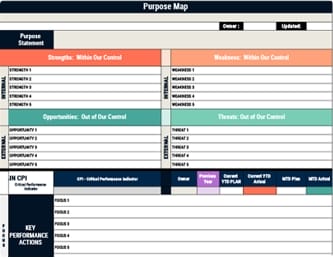

- Use tight KPIs with real-time dashboards, audits, surveys, and huddles, translating CPIs into daily KPAs for action and accountability.

- Sustain momentum via mobile recognition, cross-functional improvement teams, transparent progress updates, and aligned incentives and resources.

Why Safety and Quality Culture Matters

Although safety and quality can seem like compliance checkboxes, they’re actually core drivers of performance, trust, and financial results, because a strong culture aligns daily behaviors with clear standards, consistent feedback, and shared accountability.

When you build this culture, employees engage more deeply, take ownership of outcomes, and spot risks earlier, which raises operational excellence and improves patient results.

Data shows clear benefits: you can reduce serious injuries by 89%, lift consumer satisfaction by 28%, and strengthen reliability by lowering incidents and defects.

Reduce serious injuries by 89%, boost satisfaction 28%, and enhance reliability by cutting incidents and defects.

These gains translate into financial value, with organizations realizing up to a 340% return within three years as waste falls and rework declines.

In practical terms, you set expectations, reinforce them consistently, and measure outcomes to drive learning and performance.

Aligned organizations can grow revenue 58% faster and be 72% more profitable, underscoring how organizational alignment amplifies safety and quality culture’s impact on business results.

From Checkbox Compliance to Purposeful Commitment

When you move from checkbox compliance to purposeful commitment, you make safety and quality everyone’s job, embedding clear expectations, visible leadership, and peer accountability into daily work so standards aren’t just audited—they’re owned.

You prioritize outcomes over paperwork, using simple routines that let people spot hazards, speak up, and resolve issues before they escalate. You allocate resources accordingly, dedicating about 23% of your safety budget to initiatives that embed safety as a core value, because sustained signals shape behavior.

You reinforce ownership with peer-to-peer recognition, which can lift engagement by up to 78%, turning safe actions into norms rather than exceptions.

As commitment deepens, you reduce serious injuries—potentially by 89%—while improving HSEQ performance and retention, with strong cultures seeing 41% higher employee stay rates.

Leadership Behaviors That Set the Tone

Because culture follows what leaders do, not just what they say, you set the tone by making safety and quality visibly non-negotiable in your daily routines and decisions, not relegated to posters or audits.

Show up where work happens, conduct structured safety walks, and ask practical questions that reveal risks and improvement opportunities, then act on what you learn quickly and transparently.

Be present where work happens. Walk, ask, learn—and act fast and transparently on what you find.

Communicate priorities clearly and consistently, explaining why standards matter, how tradeoffs are decided, and what you expect from everyone, which builds trust and invites honest dialogue without fear of retribution.

Model the behaviors yourself, wear required PPE, follow procedures, and pause work when conditions change.

Recognize and reward people who surface issues and demonstrate reliability, reinforcing continuous improvement through regular feedback.

Integrate clear roles and measurable performance indicators into daily leadership routines so expectations are transparent, accountability is strengthened, and continuous improvement becomes part of how work gets done.

Empowering Employees Through Training and Engagement

Even as you set the tone from the top, you empower employees by giving them the knowledge, practice, and voice to act on safety and quality every day.

Begin with thorough training that aligns to job tasks, known hazards, and emergency response, because clarity about real work conditions drives confident action. Use diverse methods—microlearning, simulations, and gamified scenarios—to boost retention, encourage participation, and make critical steps memorable under pressure.

Form cross-functional continuous improvement teams, and give them data, charters, and time to address risks they see, which shifts behavior from passive compliance to active ownership.

Maintain ongoing education with refreshers tied to incident trends and process changes, so people can spot weak signals and prevent errors. Reinforce momentum with recognition programs that highlight specific, measurable safety contributions.

Layer in mobile-first communication and regular pulse checks to ensure frontline voices are heard, measured, and acted on, bridging trust gaps highlighted by low open communication rates across organizations.

Building Psychological Safety and Open Dialogue

Although policies and procedures matter, you build psychological safety by making it safe and expected for people to speak up, question assumptions, and surface weak signals before harm occurs.

Start by stating explicitly that reporting is rewarded, not punished, then follow through consistently, since trust grows when your actions match your words.

When employees believe they won’t face retribution, near-miss reporting can rise dramatically—sometimes by 340%—giving you earlier insight into risks.

Model the behavior you want: ask genuine questions, thank people for difficult messages, and close the loop on every concern.

Track progress with regular psychological safety evaluations to expose barriers, then address them transparently.

Use peer-led small-group sessions to normalize open dialogue, broaden participation, and share responsibility.

Measure engagement; visible leadership commitment can lift scores from 2.3 to 8.7.

Aligning leaders on clear roles and tying safety behaviors to measurable outcomes reinforces ownership and speeds adoption, reflecting the power of aligned leadership in translating intent into execution.

Smart Quality and the Role of Digital Tools

While culture sets the tone, Smart Quality turns intent into systemized practice by embedding digital tools, advanced analytics, and predictive KPI trends into everyday work so you can manage quality as a driver of value rather than a compliance afterthought. You start by selecting a modern eQMS that standardizes processes, connects deviations to root-cause actions, and feeds real-time dashboards, enabling continuous improvement and operational excellence. Next, deploy centralized training platforms and learning management systems to deliver targeted content, verify competency, and adapt curricula as risks and products evolve. Layer in behavioral analytics to track participation, adoption, and leading indicators of culture change, then refine interventions based on evidence. As programs scale, you typically realize strong business impact, with cultural transformation averaging 340% ROI within three years. To sustain momentum, regularly assess and refine the system using performance metrics and quarterly reviews so the BOS stays aligned with evolving goals.

Integrating Safety and Quality Into Daily Operations

Because safety and quality only stick when they’re embedded in the flow of work, integrate them by making risk identification, control, and learning part of every shift, not a periodic event.

Build a proactive rhythm: run brief risk assessments before tasks, use quick safety audits during operations, and capture hazards and near misses as standard practice, so you prevent harm and protect product quality.

Train continuously, not just annually, and anchor lessons in real scenarios, so employees understand protocols and feel responsible for outcomes.

Lead from the front: conduct visible safety walks, invite concerns without penalty, and close the loop with clear actions to reinforce trust and accountability.

Leverage technology—mobile recognition for safe behaviors and a learning management system—to engage, refresh knowledge, and sustain participation.

Use visual management to make performance obvious at a glance by applying color-coded indicators on team boards so everyone can spot deviations quickly and take timely action.

Measuring What Matters: KPIs and Feedback Loops

You’ve embedded safety and quality into daily work; now make performance visible by defining and tracking a tight set of KPIs and feedback loops that show whether those practices actually reduce harm and defects.

Focus on incident rates, severity rates, and LTIFR, since these quantify frequency and impact, reveal trends over time, and highlight where prevention efforts should concentrate.

Pair these metrics with regular employee surveys and structured safety audits, because they test whether protocols work in real conditions and surface gaps you can fix quickly.

Use real-time feedback loops—dashboards, huddles, and near-miss alerts—to adjust procedures immediately, preventing small issues from escalating.

When you monitor KPIs continuously and act on employee input, you build accountability, improve retention by 41%, and cut incidents considerably.

To ensure these metrics drive action, translate them into daily Key Performance Actions—observable routines like tier reviews and audits—and connect them to a few mission-critical CPIs through a CPI→KPI→KPA feedback loop.

Sustaining Momentum and Overcoming Resistance

Two moves keep your safety and quality culture advancing when the initial energy fades: remove friction to participation and make progress visible.

Open communication is your first lever, so invite concerns in real time, respond transparently, and close the loop, which builds ownership and accountability. Back this with immediate acknowledgment of safe behaviors, using simple shout-outs or digital badges that reinforce desired actions and signal what “good” looks like.

Invest in extensive training that empowers people to anticipate risks, practice proactive measures, and coach peers, since capability reduces resistance.

Pull employees from every level into decision-making, co-designing procedures and pilots to create buy-in and smoother changes. Evaluate and update risk controls routinely, publish trend improvements and milestone wins, and adjust incentives and resources to sustain commitment. Incorporate regular reviews using OKRs to keep goals visible, align efforts across teams, and maintain momentum through transparent progress tracking.

Frequently Asked Questions

How Do We Budget for Culture Transformation Without Disrupting Operations?

You budget by phasing investments, protecting frontline capacity, and tying spend to measurable milestones.

Start with a baseline assessment, then allocate a ring‑fenced fund for training, leader routines, and quick-win pilots, using off-peak scheduling to avoid downtime.

Reprioritize low‑value projects, redirect travel or discretionary budgets, and leverage internal trainers.

Build a benefits tracker, link releases to performance gains, and set quarterly gates so you adjust scope before costs or operations drift.

What Legal Implications Arise When Shifting From Punitive to Learning-Focused Approaches?

You face risks around privilege, discovery, and duty to discipline, since reflective statements and incident data can be used in litigation or regulatory actions.

You should update policies to separate just culture from willful misconduct, maintain required corrective actions, and define protected peer review channels.

Use attorney‑client privilege and statutory protections where available, anonymize trend analyses, train managers on non-retaliation, document consistent responses, and align reporting with OSHA, whistleblower, and labor obligations.

How Can Unions Be Engaged as Partners in Culture Change?

Engage unions as partners by inviting leaders into governance councils, co-designing goals, and sharing data transparently, so you build trust and shared accountability.

Establish joint training, peer-to-peer coaching, and clear escalation pathways, which align safety, quality, and staffing concerns.

Negotiate memorandum-of-understanding clauses that protect participants, reinforce just culture principles, and define metrics.

Communicate progress regularly, celebrate joint wins, and address grievances quickly, ensuring continuous feedback loops and durable, workforce-backed culture change.

What Incentives Effectively Reward Proactive Safety and Quality Behaviors?

Start with data: companies using incentives see up to 20% fewer incidents.

You should reward proactive behaviors with tiered recognition, small spot bonuses, and points redeemable for meaningful items, tying them to verified acts like near-miss reports, peer coaching, and hazard elimination.

Link team metrics to quarterly gainsharing, publish transparent leaderboards, and offer skills badges that grant access to desirable shifts.

Keep criteria objective, audit for gaming, and combine rewards with rapid feedback and supervisor praise.

How Do We Align Contractor and Supplier Cultures With Ours?

You align contractor and supplier cultures by embedding expectations in contracts, onboarding, and performance reviews, then reinforcing them with shared KPIs, joint training, and tiered oversight.

Require leaders to model behaviors, mandate incident and near-miss reporting standards, and audit against the same playbook you use internally.

Incentivize proactive improvements, apply corrective actions consistently, and hold quarterly alignment reviews.

Use preferred vendor status, transparent scorecards, and consequence management to sustain alignment.

Conclusion

You’re ready to move from compliance to commitment by setting clear expectations, modeling visible leadership, and integrating safety and quality into daily work. Equip teams with training, digital tools, and psychological safety so they identify risks early and act decisively. Use meaningful KPIs and feedback loops to track progress, correct drift, and sustain momentum. Ask yourself: can your operations run a day without checklists yet still perform safely? If not, keep aligning behaviors, resources, and accountability until they can.