By coincidence, the moment you replace paper forms with mobile checklists, your Gemba walks start producing actionable data. You standardize observations, tag issues with photos and QR codes, and trigger automated workflows that notify the right people, while timestamps and signatures create traceability. Dashboards surface bottlenecks against KPIs, and 4C cycles track fixes through confirmation. You’ll also address deployment, security, and access control choices next—because the real gains appear when the system fits your floor.

Key Takeaways

- Use digital checklists with required evidence to standardize observations and reduce errors across shifts and sites.

- Integrate real-time data capture (photos, QR codes, timestamps) to accelerate issue identification and accountability.

- Automate workflows to assign owners, set due dates, and escalate overdue actions for faster closure.

- Connect dashboards to KPIs (throughput, downtime, quality) to prioritize fixes and validate ROI with finance.

- Align deployment with IT: choose cloud/on‑prem, enable SSO, configure APIs, and enforce role-based security.

The Shift From Paper to Digital on the Shop Floor

While paper checklists once anchored shop floor routines, the shift to digital Gemba Walks streamlines how you capture, analyze, and act on operational data. You move from slow, error-prone handwriting to structured digital forms that guide observations, enforce required fields, and cut transcription mistakes.

With real-time data capture, you evaluate processes on the spot, compare results across shifts, and flag anomalies before they escalate, which accelerates decisions and increases accuracy.

Real-time capture lets you evaluate instantly, compare across shifts, and flag anomalies before they escalate.

You also document with photos and short videos, so issues are clearer and less open to interpretation, enabling faster root-cause discussion.

Digital tools let you create and assign actions immediately, track status, and verify closure, which strengthens accountability. As teams comment, share evidence, and align follow-ups, you build cross-department collaboration and a practical, continuous improvement habit.

Integrating mobile-first tools into digital Gemba Walks ensures frontline workers are included, feedback is captured in real time, and engagement metrics can be tracked to measure cultural transformation progress.

Core Capabilities of Modern Gemba Walk Software

Building on the move to digital walks, modern Gemba walk software equips you with a focused toolkit that standardizes observations, accelerates decisions, and protects your data end to end. You’ll replace paper with digital checklists that guide consistent data capture, reduce transcription errors, and speed completion, ensuring comparable results across shifts and sites. You can configure fields, required evidence, and scoring to match standards, then trigger automated workflows that route findings to owners, set due dates, and escalate overdue actions. Customizable dashboards and reports turn observations into trends, so you can segment by line, product, time, or root cause and prioritize fixes. Collaboration tools connect frontline staff and managers, enabling shared notes and follow-ups. Strong security, including role-based permissions and encryption, safeguards sensitive operations. To sustain momentum post-walk, integrate dashboards with governance rhythms that enable regular progress tracking and accountability across teams.

Real-Time Data Capture: Photos, QR Codes, and Signatures

Two real-time capture tools—photos and QR codes—turn your Gemba walk into a precise, verifiable record that speeds corrective action and strengthens accountability.

Use photos to document conditions as you see them, attaching clear evidence to each observation, then scan QR codes on machines, parts, or locations to pull up specs, histories, and maintenance data without delay. This pairing links issues directly to relevant data points, reducing ambiguity and shortening investigation cycles.

Pair photos with QR scans to tie issues to data, cut ambiguity, and speed investigations.

Add digital signatures to close the loop. Have operators, supervisors, or auditors acknowledge findings and action items on the spot, creating a traceable chain of responsibility.

With time-stamped images, scans, and signatures, you improve evaluation accuracy, support timely decisions, and meet compliance requirements, while reducing documentation errors and accelerating operational adjustments across shifts.

To reinforce fast decision-making and ownership, mirror these captures on visual management boards with color-coded indicators so teams can spot deviations at a glance and act immediately.

Dynamic Checklists Powered by Lean and TPM

One powerful way to standardize your Gemba walk without slowing it down is to deploy dynamic checklists that embed core Lean and TPM principles, guiding what you look for, how you record it, and when you trigger action.

You tailor each checklist to your processes, aligning prompts with value stream steps, equipment care standards, and common loss categories, so observations stay relevant and comparable across shifts.

Use structured fields to capture defects, delays, and abnormal conditions, then attach photos or counts for clarity.

Because entries update in real time, you can spot inefficiencies quickly and prioritize what matters.

Share checklists with teammates to align on evidence, not opinion, and use trend views to surface recurring gaps, drive standard work updates, and support continuous improvement.

Integrate real-time alerts that escalate when KPIs deviate, reinforcing clear expectations and accountability to sustain high-performance team behaviors.

Issue Lifecycle Management With the 4CS: Capture, Collaborate, Correct, Confirm

Although every Gemba walk surfaces many observations, the 4Cs—Capture, Collaborate, Correct, Confirm—give you a disciplined lifecycle to turn them into results.

You start by capturing issues in real time with digital tools, attaching photos, timestamps, and locations so evidence is precise and searchable, then assigning owners and due dates to prevent drift.

Next, you collaborate through integrated chat, mentions, and checklists, aligning operators, supervisors, and engineers on the problem definition and constraints, while documenting hypotheses and decisions in one thread.

Collaborate in one thread—chat, mentions, checklists—to align teams, define problems, and document decisions.

You then correct by implementing data-driven countermeasures, selecting the simplest solution that addresses root causes, and standardizing updates to methods or settings.

Finally, you confirm by tracking outcomes against expectations, validating effectiveness, closing actions, and escalating anything that regresses.

As you implement the 4Cs, reinforce strategic alignment by setting clear objectives and measurable KPIs, similar to how OKRs help turn broad goals into actionable steps.

Analytics and Reporting for Continuous Improvement

When you digitize Gemba Walks, analytics and reporting turn observations into measurable progress by capturing structured data through dynamic checklists, aggregating it in real time, and translating it into clear insights you can act on quickly.

You standardize inputs, reduce ambiguity, and create a reliable dataset that supports trend analysis across shifts, lines, and sites.

Use automated reporting to generate customizable spreadsheets and PDFs, then schedule them to surface KPIs, recurring bottlenecks, and safety hotspots without manual effort.

Real-time dashboards highlight deviations as they occur, so you can prioritize issues, assign actions, and verify impact.

Integrate these analytics with your problem-solving cycle, linking findings to root causes, countermeasures, and confirmations.

As adoption matures, you’ll see reduced downtime and measurable productivity gains.

Well-aligned organizations use these insights to reinforce vertical and horizontal alignment, improving collaboration and accelerating decision-making for better business results.

Deployment, Security, and Access Control Considerations

Before you roll out digital Gemba Walks, establish a deployment plan that balances speed, integration, and security, so the solution delivers value on day one without exposing sensitive operations.

Choose your hosting model early: deploy on Mendix (AWS) cloud for rapid setup and managed scalability, or go on‑premise if your policies require full control of data and network boundaries.

Map integrations to existing systems, validate single sign‑on, and configure APIs so data flows reliably without duplications.

Harden security from the start. Define role‑based permissions so supervisors, operators, and auditors see only what they need, and apply least‑privilege by default.

Enable encryption in transit and at rest, enforce strong authentication, and review authorization logs.

Provide real‑time access via dashboards and results tabs while restricting exports and mobile offline use.

To sustain adoption and clarity across teams, align your deployment with Strategic Alignment principles so objectives, roles, and communication reinforce a shared vision.

Measuring ROI and Impact on Operational Excellence

How do you quantify the value of digitized Gemba Walks so leaders can act with confidence and teams see clear wins? Start by tying outcomes to baselines, then measure changes in throughput, downtime, and quality.

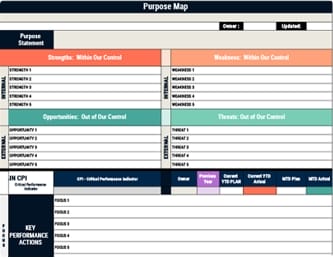

You’ll see ROI quickly when productivity rises 11%, 13+ extra batches ship annually without new resources, and downtime drops by 4,500 hours due to real-time data and faster fixes. Convert these gains into dollars using standard labor, capacity, and scrap rates, then compare to software and training costs. Add a simple CPI→KPI→KPA loop by defining Critical Performance Indicators first, mapping supporting KPIs, and enforcing daily KPAs so improvements are owned, visible, and coachable.

1) Define KPIs before go-live, including safety, compliance, and first-pass yield, so improvements are unmistakable.

2) Instrument issue tracking, linking findings to root causes, owners, and closure times for cycle-time visibility.

3) Review results monthly, validate savings with finance, and reinvest gains into continuous improvement.

Frequently Asked Questions

How Do We Secure Operator Buy-In and Reduce Change Resistance During Rollout?

Secure buy-in by involving operators early, explaining the “why,” and linking changes to safety, quality, and less rework.

Co-design workflows with pilot teams, gather feedback, and fix pain points quickly.

Provide hands-on training, job aids, and peer champions, while recognizing early adopters.

Communicate timelines, metrics, and success stories, and maintain open channels for concerns.

Start small, iterate, and retire redundant tasks, so operators see clear benefits and trust the rollout.

What Training Formats and Durations Work Best for Frontline Adoption?

Start with microlearning bursts, 10–15 minutes, because everyone loves hour-long lectures—said no operator ever.

You’ll run 3–5 modules over two weeks, each covering one task, with demo, guided practice, and quick quiz.

Add on-the-job coaching: 5–10 minute huddles per shift for the first week.

Offer self-serve videos and printable one-pagers.

Cap it with a 30-minute capstone scenario, verifying proficiency, documenting gaps, and setting refresher cadence monthly.

How Should We Redesign Roles and Incentives Around Digital Gemba Behaviors?

Redesign roles by defining clear digital observation, follow-up, and coaching responsibilities, then map them to operators, team leads, and managers with explicit handoffs.

Tie incentives to leading behaviors—timely logged observations, data quality, closed actions, and problem-solving cycles—rather than raw counts.

Use tiered recognition, small monetary bonuses, and advancement pathways.

Provide time allowances and simple SOPs, embed metrics in reviews, and rotate ownership to build capability while preventing compliance fatigue.

How Do Unions and Worker Councils Factor Into Deployment Planning?

You bring unions and worker councils in early, since 73% of union contracts touch technology or data use.

You brief representatives on scope, data flows, and change impacts, then co-design guardrails on surveillance, metrics, and discipline.

You negotiate role definitions, training time, and opt-out or grievance pathways, aligning with CBAs.

You pilot with joint oversight, publish findings transparently, and adjust.

You formalize governance committees, review audits regularly, and schedule renewal checkpoints.

What Data Governance Policies Are Needed for Multimedia Evidence Retention?

You need policies defining lawful purpose, data minimization, clear retention schedules by type, and precise deletion triggers, plus chain‑of‑custody rules for integrity.

Specify roles for capture, tagging, review, and approval; require consent handling, notice, and access controls.

Mandate encryption at rest and in transit, hashing for tamper detection, and detailed audit logs.

Establish subject access, redaction, and disclosure procedures, vendor and cross‑border safeguards, periodic risk assessments, and documented incident response.

Conclusion

By digitizing Gemba walks, you turn observations into actionable data, moving from guesswork to guided decisions like switching on a lighthouse in fog. You’ll standardize checklists, capture issues in real time, and manage the 4Cs to close loops quickly, while dashboards reveal trends and ROI. Start small, secure access, train teams, and iterate, because consistent use drives results. With disciplined deployment, you’ll reduce waste, accelerate fixes, and anchor continuous improvement directly on the shop floor.