To build a culture of extreme ownership on the factory floor, you set clear expectations, define decision rights, and model calm accountability under pressure, then back it with simple visual controls, tight feedback loops, and daily huddles. You train for cross-skill depth, delegate authority with guardrails, and track a few leading metrics that tie to safety, quality, and takt. You recognize responsible risk-taking and root-cause rigor—because without these habits, improvement stalls at the first constraint.

Key Takeaways

- Model accountability: leaders own outcomes, explain decisions, and state next steps to normalize responsibility and learning from mistakes.

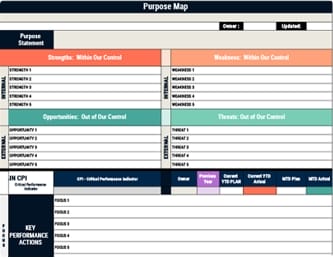

- Define roles, decision rights, and OKRs so everyone knows what they own and how it ties to strategic objectives.

- Institutionalize communication: daily stand-ups, visual boards, and clear metrics to surface issues early and trigger fast actions.

- Build psychological safety: invite risks and questions, separate people from problems, and close loops quickly on raised issues.

- Align metrics, incentives, and recognition to ownership behaviors, with transparent rules and timely rewards tied to quality, safety, and throughput.

Why Extreme Ownership Matters on the Factory Floor

Ownership is the lever that turns a busy factory into a reliable, high-performing operation, because when every person accepts responsibility for outcomes—not just tasks—you reduce errors, speed up problem resolution, and lift overall productivity.

Ownership turns a busy factory into a reliable powerhouse by driving accountability, faster fixes, and higher productivity.

When you practice Extreme Ownership on the floor, you treat defects, delays, and quality misses as your problem to surface and solve, which raises morale because everyone knows their effort matters and their voice is heard.

You cut production errors by catching risks early, documenting findings, and fixing root causes before they spread. You also shorten downtime by escalating issues quickly and coordinating cross-shift handoffs with clear, transparent communication.

As decision rights become clearer and initiative is rewarded, your team’s productivity can climb by roughly 30%, improving output quality and customer satisfaction.

Integrating Six Sigma practices with Extreme Ownership further reduces defects and stabilizes processes through DMAIC, enabling teams to sustain higher quality and efficiency on the factory floor.

Leadership Behaviors That Set the Standard

A leader sets the tone for Extreme Ownership by modeling accountability in visible, practical ways, taking responsibility for outcomes, explaining decisions, and showing how to recover from mistakes without blame.

You set the standard when you own both wins and failures, state what you’ll do next, and make the reasoning clear so people understand priorities and trade-offs. Communicate roles, objectives, and constraints in plain language, then check for understanding, because alignment beats assumptions on the line.

Show appropriate vulnerability by naming your errors and describing the fix, which encourages smart risk-taking and faster learning.

Reinforce Extreme Ownership daily by delegating authority with clear boundaries, asking for proactive updates, and expecting informed decisions. Give timely feedback, recognize specific contributions, and link actions to results to strengthen personal ownership.

To strengthen alignment, use OKRs to translate strategic objectives into measurable key results that clarify priorities across teams.

Building Trust and Psychological Safety

Trust starts with consistent signals that it’s safe to speak up, raise concerns, and experiment without punishment, and you build those signals into daily routines, not posters.

You open every shift with a short check-in, ask for risks and lessons learned, and thank people for candor, even when results miss the mark.

You respond to errors with curiosity first, separating the person from the problem, and you share what you’ll do differently so improvement is mutual.

You normalize questions on the floor, pair veterans with newer operators, and rotate facilitation so voices diversify.

You close loops quickly, reporting back on raised issues, which proves speaking up leads to action. As trust grows, communication sharpens, collaboration accelerates, morale stabilizes, and people take ownership, improving quality, safety, and throughput.

To reinforce this, use mobile-first tools and real-time feedback to reach frontline workers and act on insights, which builds trust and accelerates change through employee engagement metrics.

Clear Roles, Responsibilities, and Decision Rights

Even before you push for higher throughput, you need crisp role definitions, unambiguous responsibilities, and explicit decision rights so people know what they own, what they influence, and what they must escalate.

You set clear boundaries for each role, link responsibilities to outcomes, and assign decisions to the people with the best expertise, which reduces confusion and accelerates problem-solving.

Publish expectations for individual performance so you can track progress, spot gaps early, and coach without ambiguity, then review and adjust roles as projects evolve to maintain adaptability and continuous improvement.

Aligned organizations can grow revenue faster and be more profitable when roles and decisions are clearly connected to strategy, reinforcing organizational alignment across teams.

- Define each role’s purpose, core tasks, and authority limits, then document them where everyone can see.

- Map decision rights by topic, owner, backup, and escalation path.

- Tie responsibilities to measurable KPIs and due dates.

- Run scheduled role reviews to realign workloads and eliminate overlaps.

Communication Rituals and Visual Management

In manufacturing environments, you build extreme ownership by institutionalizing communication rituals and visual management that make progress, risks, and priorities unmistakably clear to everyone on the floor and in support roles. Run daily stand-ups at shift start, keep them short, and cover safety, yesterday’s results, today’s plan, and known constraints, so every person knows what matters and who owns which tasks. Use Kanban boards, progress charts, and andon-style cues to show real-time status, expose bottlenecks, and trigger timely countermeasures. Embed a structured feedback loop—what worked, what didn’t, and immediate actions—to normalize open dialogue and capture improvements. Post visual metrics for output, quality, and safety, update them at set times, and review them weekly, celebrating wins and assigning owners for problems. Add color-coded indicators aligned to clear standards so teams can quickly spot deviations and act on them using real-time data visualization.

Empowerment Through Delegation and Skills Development

While visual management makes work visible, you cement extreme ownership by delegating real responsibility and systematically building skills so people can act with confidence.

Assign outcomes, not tasks, then match them to people whose capabilities you’re actively growing, because empowerment works when scope and skill align. Use mentorship and targeted training so each person can make informed decisions at the line, in maintenance, or in scheduling, which boosts output and morale. To reinforce this, ensure leaders consistently communicate how each role ties to strategy and shared values, since strong organizational alignment raises engagement and performance.

- Define the objective, success criteria, and guardrails, then let the owner choose the method.

- Pair veterans with rising operators in mentorships, and track skills with a simple matrix.

- Schedule short, recurring trainings tied to real jobs, followed by immediate application.

- Review workload balance and rotate responsibilities to broaden competence and resilience.

You’ll see superior productivity, higher pride, and stronger retention.

Accountability, Feedback Loops, and Continuous Improvement

Because ownership only sticks when results are visible and reviewed, you build accountability by defining who owns each outcome, how success will be measured, and when progress will be checked.

Then you close the loop with fast, structured feedback that drives the next improvement. You set clear standards for quality, timing, and safety, then verify performance at regular intervals so gaps are spotted early and errors are reduced.

You run brief, scheduled feedback sessions on the shop floor, focusing on facts, root causes, and next actions, which encourages open communication and quick learning.

You capture insights from operators, technicians, and leads, translate them into simple experiments, and track results to confirm impact.

Done consistently, this mindset typically lifts productivity 10–30% while boosting job satisfaction and retention.

To sustain momentum and adaptability, establish regular governance rhythms that connect frontline actions to aligned OKRs and use performance dashboards to track progress and inform resource allocation.

Metrics, Incentives, and Recognition That Reinforce Ownership

Clear feedback loops only gain power when you attach them to metrics, incentives, and recognition that make ownership visible and rewarding. You should define a small set of metrics that track individual and team performance against production, quality, and safety goals, then review them regularly so everyone sees cause and effect. Tie incentives directly to these measures, using transparent rules and timely payouts, because alignment breaks when rewards feel arbitrary. Recognize people who model extreme ownership publicly, since attention legitimizes desired behavior and sets a clear standard. Drawing from leaders like Tesla and Spotify, align measures and rewards to clear objectives and routine progress reviews, using frameworks like OKRs to turn goals into actionable steps. – Set clear goals, publish dashboards, and compare plan vs. actual to surface ownership gaps. – Link bonuses to target attainment, quality yield, and first-pass success. – Hold structured feedback sessions using metric trends and actions. – Enable peer recognition to reinforce shared ownership.

Frequently Asked Questions

How Do We Introduce Extreme Ownership to Unionized Environments Respectfully?

Start by aligning extreme ownership with existing contract rights, then co-create principles with union leaders, framing ownership as shared problem-solving, not blame.

Explain roles, decision boundaries, and escalation paths, and integrate just-culture practices so reporting issues isn’t punished.

Pilot on safety or quality, track metrics jointly, and celebrate fixes, not heroes.

Provide training for stewards and supervisors, embed ownership language in SOPs, and review outcomes in labor-management meetings for continuous refinement.

What Onboarding Practices Instill Ownership in New Manufacturing Hires?

Start with clear role expectations tied to measurable outcomes, then run hands-on simulations where you own a task from setup to quality checks.

Pair with a mentor who models accountability, and use checklists that require your sign‑off on safety, quality, and throughput.

Review mistakes in blameless debriefs, assign corrective actions, and track progress.

Teach basic problem‑solving, root‑cause methods, and escalation paths, and close each day with brief reflections on lessons and next steps.

How Does Extreme Ownership Adapt During Mergers or Plant Consolidations?

Seventy percent of mergers miss synergy targets, so you adapt by tightening role clarity and decision rights, then mapping owners to every critical process.

You establish a single escalation path, standardize KPIs across sites, and run daily cross-plant huddles where you report wins, defects, and risks.

You execute rapid A3 problem-solving, verify countermeasures with layered audits, and protect customer commitments first, while you sunset duplicate processes with clear cutovers and measured accountabilities.

What Digital Tools Best Support Ownership in Hybrid or Multi-Site Operations?

Use a unified digital stack: a cloud MES for real-time production visibility, an EAM/CMMS for asset ownership, and QMS workflows for deviations and CAPAs.

Add collaborative task boards like Jira or Trello for cross-site accountability, and OKR software to align outcomes.

Deploy digital work instructions and e-signatures for traceability, plus IoT dashboards for alerts.

Standardize data with APIs, enforce RACI in tools, and require post-incident reviews with owner-assigned actions.

How Can Night-Shift Crews Sustain Ownership Without On-Site Leadership Presence?

Picture lighthouse keepers swapping logs at dawn; you’ll mirror that.

You sustain ownership by using clear SOPs with checklists, defining on-call escalation paths, and rotating a night-shift lead who owns handoffs and metrics.

Stand up brief start/stop huddles, log issues in a shared system, and timestamp decisions.

Track two or three KPIs nightly, post them visibly, and debrief weekly.

Pair new operators with mentors, rehearse contingencies, and audit adherence.

Conclusion

You can build extreme ownership by setting clear standards, investing in skills, and reinforcing accountability through visible metrics and consistent feedback. Start small, then scale: define decision rights, run tight huddles, and reward initiative publicly. One compelling data point: plants with high psychological safety see up to 40% fewer quality defects, because people flag issues early. As you align roles, rituals, and incentives, you’ll create a disciplined system where everyone owns outcomes and continuous improvement becomes routine.