You start by defining clear objectives, a concise vision, and measurable success metrics aligned to strategy, then build a culture of continuous improvement where small experiments and transparent learning are routine. Next, map and prioritize core processes, model workflows with ownership, and form cross‑functional teams. Identify bottlenecks, reduce waste, and automate only where it adds value, using data and governance to guide choices. Finally, monitor performance, reward wins, and iterate—because the next step changes everything.

Key Takeaways

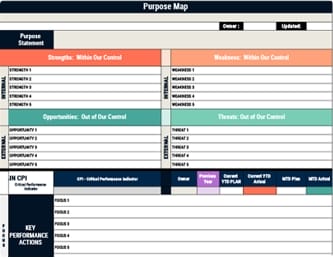

- Define clear OpEx objectives, success metrics, and weightings; align with strategy, select a BPM tool, and secure executive sponsorship.

- Build a continuous improvement culture with Kaizen cadences, lightweight idea templates, data-driven experiments, and transparent feedback loops.

- Catalog and prioritize processes using a weighted matrix; model top candidates with swimlanes to expose bottlenecks and waste.

- Form cross-functional teams with defined ownership, governance, decision rights, and escalation paths; include external partners when flows depend on them.

- Remove bottlenecks via queue and wait-time analysis, cut non-value tasks, target rework using RTY, and automate stable, high-volume activities.

Define Objectives, Vision, and Success Metrics

Before you jump into redesigning workflows, anchor your improvement effort by defining clear objectives, a shared vision, and success metrics that translate strategy into day-to-day decisions. Start by aligning OpEx objectives with the organizational vision, then set specific goals, such as reducing process cycle time by a defined percentage within 12 months. Establish measurable criteria across key processes—hit ratio, regulatory compliance, and combined ratio—and apply weightings from 0.5 to 1.5 to focus resources where impact is greatest. Define a BPM strategy and select a tool like ADONIS to map inputs, activities, outputs, and metrics consistently. Communicate objectives organization-wide and secure executive sponsorship to ensure alignment and accountability. Create a governance cadence with milestones and dashboards to track progress and adjust. Add governance rhythms with regular progress tracking to improve performance visibility and sustain alignment across teams.

Build a Culture of Continuous Improvement

With objectives, metrics, and governance in place, you now need to embed improvement into daily work so progress doesn’t stall after kickoff. Build a culture where people experiment, share lessons, and act on data, because continuous improvement thrives when employees feel safe to surface problems and propose fixes. Give teams simple methods, clear roles, and tools that make collaboration and documentation effortless, then reinforce behaviors with recognition and routine.

Embed improvement into daily work: experiment, share lessons, act on data, and reinforce with routine.

- Empower people to spot inefficiencies and suggest changes, using lightweight templates that capture issues, root causes, and quick wins.

- Involve employees directly in optimization efforts to increase ownership, decision quality, and sustained adoption.

- Equip teams with collaboration platforms, such as ADONIS, to manage ideas, workflows, and feedback loops.

- Establish regular Kaizen cycles, with defined cadences, measurable goals, and visible outcomes.

Leverage Six Sigma to systematically reduce defects and sustain improvements through the DMAIC approach and data-driven control.

Map, Prioritize, and Model Core Processes

How do you turn broad improvement intent into targeted action? Start by creating a process master that catalogs every value-chain process, such as regulatory compliance or new product development, and document inputs, activities, outputs, customers, and key metrics like cycle time and error rates, so you establish a common baseline. Aligned organizations can swiftly adapt to market changes, so ensure your process catalog reflects and reinforces shared values and clear communication to maintain cohesion and responsiveness across teams. Next, build a prioritization matrix that scores each process against weighted success criteria, using weights from 0.5 to 1.5 and anchors from 1 to 5, which lets you rank where to focus. Then model the top candidates with swimlane diagrams that show department lanes, third-party actors, activities, decisions, and handoffs, enabling you to see non-value-adding steps. Use these models to pinpoint bottlenecks, excessive handoffs, and opportunities to improve downstream rolled throughput yield and reduce rework.

Assemble Cross-Functional Teams and Assign Ownership

Why wait to formalize ownership when the next improvement cycle hinges on it? Assemble a cross-functional team that includes representatives from every impacted area, an executive sponsor, a process supplier, a process owner, and process participants and consumers, so you capture end-to-end realities and accountability. Invite key external parties—vendors and clients—when their inputs or outputs affect flow, because interdependencies and handoffs span your value chain. To strengthen cohesion and ensure clarity across roles and teams, incorporate vertical alignment practices that promote a clear flow of information from leadership to employees.

- Define roles and responsibilities, tying each role to output quality, timeliness, and measurable performance, so ownership is unambiguous.

- Set a cadence of structured problem-solving sessions, using root cause analysis and Pareto data, to keep improvements evidence-based.

- Create formal governance with decision rights, escalation paths, and milestone reviews to prevent scope creep.

- Track commitments visibly to sustain engagement and pace.

Remove Bottlenecks, Reduce Waste, and Automate Wisely

Sooner rather than later, map your process data to locate the true constraint—the slowest step or the resource running hottest—because relieving that bottleneck will unbolt the biggest gains in throughput and cycle time. Use queue lengths, wait times, and utilization to pinpoint it, then elevate capacity, streamline work, or rebalance load to protect flow.

Reduce waste next by removing non-value-adding steps, unnecessary handoffs, and waiting, since each cut raises throughput and lowers costs. Apply RTY to see how small defects, rework loops, and minor delays compound, then target the few steps that degrade overall yield the most.

Automate wisely by selecting high-frequency, rule-based tasks with stable inputs, building reliability and consistency while keeping humans for exception handling and judgment. Engage frontline staff to validate problems and co-design practical fixes. To sustain improvements and build trust, pair these changes with regular employee feedback loops via mobile-first tools so frontline workers feel heard and vital updates reach everyone.

Monitor Performance, Reward Wins, and Iterate Relentlessly

With bottlenecks relieved and waste trimmed, you now need to lock in gains by measuring what matters, seeing results in real time, and course-correcting fast. Define KPIs that align with your OpEx objectives, translate goals into process lifecycle indicators, and set targets that make accountability clear. Track both leading and lagging indicators to show cause and effect between each pillar you implemented and the performance outcomes achieved.

Measure what matters, monitor in real time, and course-correct fast to lock in operational excellence.

- Build visual dashboards that surface cycle time, WIP, RTY trends, and bottlenecks, so teams see performance and act quickly.

- Establish data governance, ensuring data quality, ownership, and cadence, which keeps KPI tracking trustworthy and timely.

- Run frequent reviews, compare trends to targets, and implement corrective actions with owners and deadlines.

- Recognize wins publicly, standardize what works, and iterate relentlessly to sustain momentum and adapt to change.

Integrate ongoing assessments with Balanced Scorecards and performance dashboards to foster transparency, accountability, and timely strategic adjustments.

Frequently Asked Questions

How Do We Budget for Process Improvement Without Derailing Operations?

Allocate a modest baseline budget, then fund improvements in staged tranches tied to measurable milestones, so you don’t overcommit.

Prioritize high‑impact, low‑disruption projects, and schedule pilots during low‑demand periods to protect throughput.

Ring‑fence operational funds, and create a contingency buffer for overruns.

Track ROI with clear KPIs, reinvesting verified savings into the next tranche.

Use cross‑functional teams, standard change controls, and clear communication to limit downtime and maintain service levels.

Which Tools Integrate Best With Our Existing Tech Stack?

You’ll get the best integration by prioritizing tools that match your stack’s core platforms. If you’re on Microsoft 365/Azure, choose Power Automate, Power BI, and Dataverse; for Google, use AppSheet and Looker Studio. With AWS, consider Step Functions, Lambda, and QuickSight; for Salesforce, use Flow, MuleSoft, and Tableau. Ensure RESTful APIs, webhook support, SSO (SAML/OIDC), and robust SDKs. Validate with a pilot, monitor latency and data quality, then standardize connectors.

How Do We Manage Change Fatigue Among Frontline Employees?

Overwhelmed by constant initiatives? You manage change fatigue by pacing releases, setting clear priorities, and protecting capacity with no‑change windows. You brief frontline staff early, explain the why, and show task‑level impacts, then provide simple job aids and just‑in‑time training. You assign local champions, gather weekly feedback, and close the loop visibly. You measure load with a change calendar, rotate pilots, and celebrate small wins, while removing low‑value changes to reduce noise.

What Governance Model Ensures Process Changes Remain Compliant?

Use a two-tier governance model: a cross-functional Process Governance Board and embedded Process Owners. You define standards, risk controls, and approval gates, while Process Owners map changes to policies, regulations, and controls. You require documented impact assessments, legal and compliance sign-off, and segregation of duties for design, testing, and release. You enforce version control, training, and monitoring with KPIs and audits, and you escalate exceptions through a defined waiver process.

How Soon Should We Expect Measurable ROI?

Expect measurable ROI within 8–12 weeks for quick wins; think of it like planting seeds that sprout fast while deeper roots form. You should set a baseline now, define a few leading indicators, and track weekly.

Prioritize high-volume, low-complexity processes first, because they deliver early gains, then layer larger initiatives that mature over 6–12 months.

Include costs of change, adoption rates, and defect reductions, so your ROI model reflects both speed and sustainability.

Conclusion

You’ll reach operational excellence by defining clear goals, building daily improvement habits, mapping and owning core processes, and fixing bottlenecks with data, governance, and smart automation. Start small, then scale what works. For example, a regional clinic cut patient wait times 35% in eight weeks by modeling intake steps, assigning a flow lead, removing duplicate forms, and automating appointment reminders, then tracking cycle time daily. Monitor results, celebrate wins, and iterate so gains compound and remain sustainable.